Maintaining the freshness, nutritional value, and overall quality of fruit and vegetable relies on the journey they take from harvest to consumption. Any company in this industry needs to make sure their products are safe and healthy, especially now that fruit and vegetables become more and more important segment in the food market and more and more consumers are interested in maintaining healthy and balanced vegetable-based diet.

If you want to make sure your fruit and vegetable production line runs smoothly, read further and learn more about our products that will help you solve these problems.

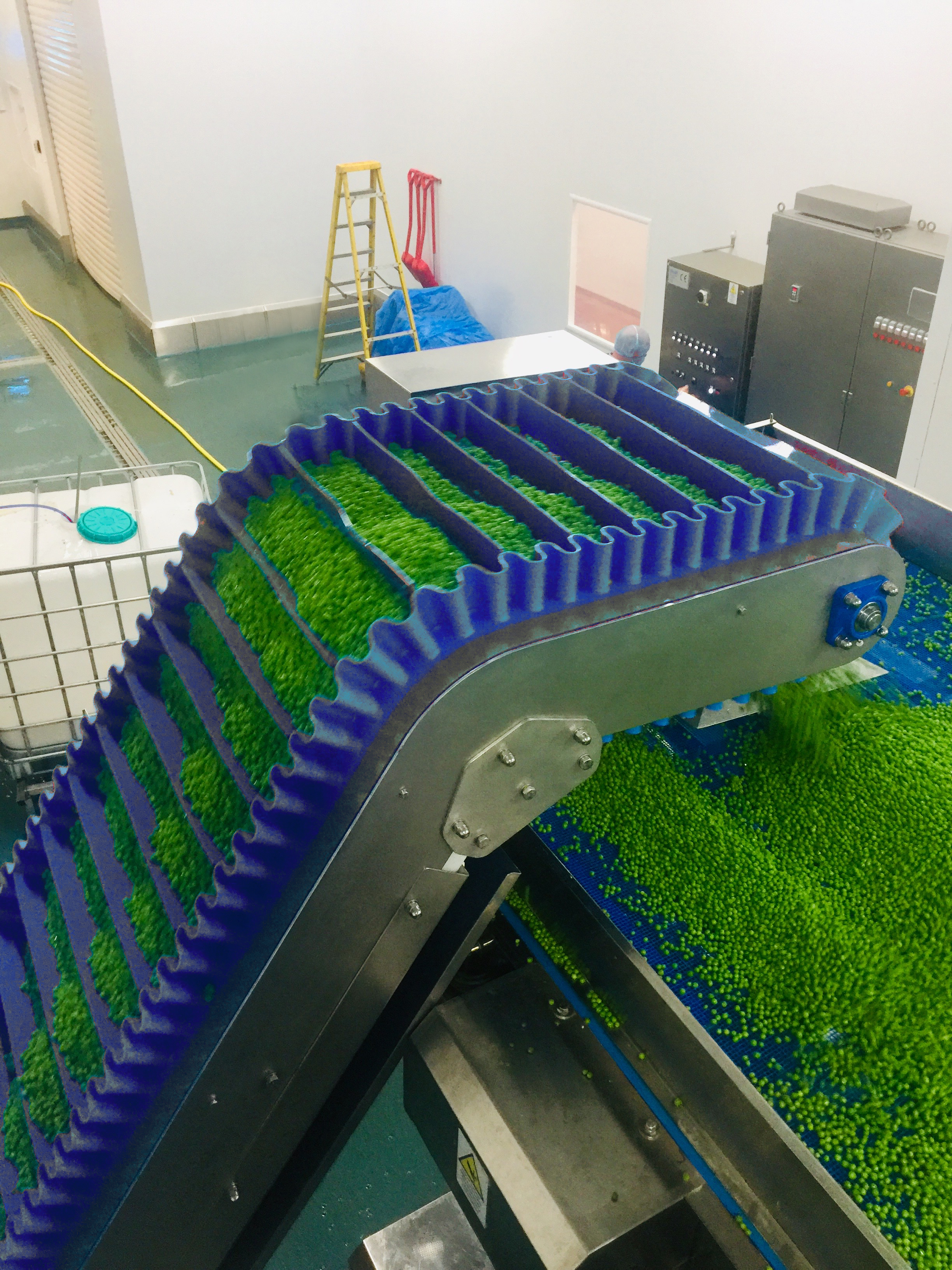

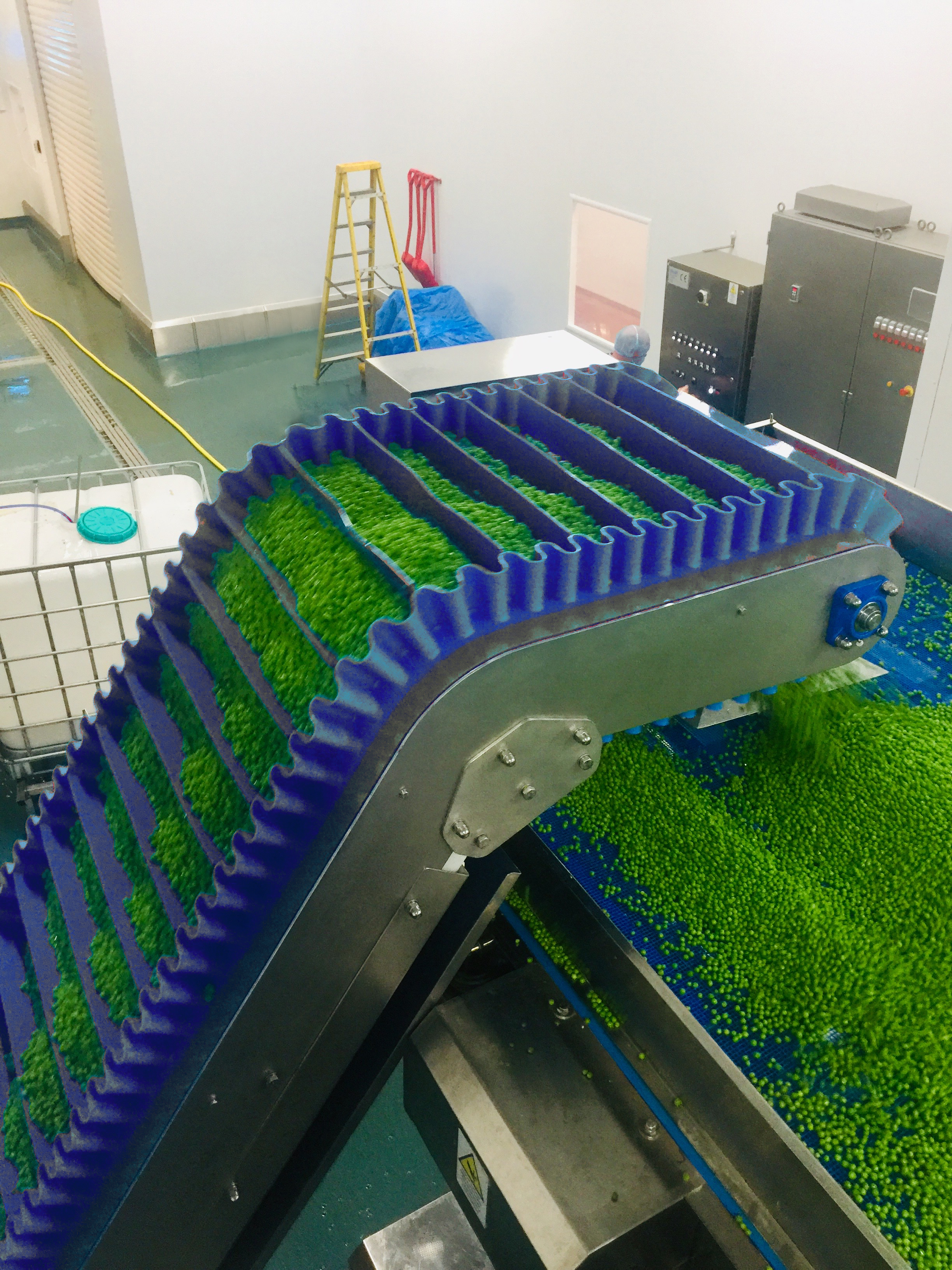

Conveying belts for every stage fruit and vegetable processing

Ammeraal Beltech is heavily involved in the food processing industry, particularly in the fruit & vegetable segment. Proudly standing as a leading manufacturer of process and conveyor belts, especially tailored for the Food Industry, we're consistently developing new products and solutions with an unwavering focus on food hygiene.

Conveyor belt is not just a mover of goods. Its role becomes paramount in the stages that follow harvest. Our belts can be used in all stages of fruit & vegetable processing:

- Receiving and feeding,

- Trimming – as goods move on the belt, sharp blades take away extra bits, so what's left is just the fresh, healthy part of each piece, enhancing aesthetic appeals and providing consumers with consistent, enjoyable products.

- Cutting,

- Washing. Cleansing food, ridding them of soil, pesticides, and contaminants to not just enhance the visual appeal of the vegetables but also, more importantly, safeguards consumers health. A key sanitization step in the fresh-cut produce production chain.

- Dewatering and drying

- Optical sorting,

- Blanching,

- Cooking,

- Pasteurization,

- Cooling,

- Freezing,

- Packaging,

- Logistics.

Our solutions can be used for conveying:

- Fresh products

- Fresh cut products,

- Canned products and preserves,

- Frozen and deep-frozen products,

- Ready-to-eat products packed in trays or in bags,

- Pre-cooked products.

Key features of conveying belts in fruit and vegetable handling

- Food grade. These belts are specifically crafted to meet the hygienic demands of the fruit and vegetable segment, ensuring that there is no risk of contamination during the processing of goods. Our food grade belts comply with EC 1935/2004, EU 10/2011 and FDA standards supporting your ISO 22000 requirements (previously HACCP).

- Antimicrobial. These belts prevent the growth of microorganisms and ensure a more hygienic environment.

- Non-fraying edges. Our non-fraying edges guarantee that the edges of the belt remain intact over time, making sure there is no case when frayed edges could potentially damage or contaminate the fruits and vegetables being transported.

- Fabrics that are flexible or stable. Flexible fabrics can adapt to the contours of the produce and the processing equipment, allowing for smoother transitions and reduced wear, whereas stable fabrics are crucial for handling heavy loads and ensuring that the belt maintains its structure.

- X-ray and metal detectable features. A great step forward in food safety, protecting consumers from the risk of pollution from broken plastic belt parts. XMD belt range is detectable by metal-detectors and X-rays, as it is made from a food-grade detectable compound present in belt’s body and accessories.

Ammeraal Beltech range of products for fruit and vegetable processing

We offer various types of belting solutions, such as mesh, homogeneous, modular and synthetic belts, to cater to the needs of this industry.

Ultrascreen mesh belts find their primary application in the dewatering and drying of freshly washed and cut vegetables. Diverse mesh sizes can be used according to the required permeability in the process and product size. Ultrascreen Belts are also used in cooling processes, recycling of used washing water, wastewater treatment, filtering, weighting, sieving, and squeezing. They ensure deep sanitation and allow processing sticky wet products, avoiding any damages on the processed goods.

- Ultrascreen PRO has been designed for the unique challenges of fruit and vegetable processing, offering self-tracking, no slippage, plug & play (no run-in time) and extended life time.

- Ultrascreen XMD goes with X-ray and metal-detectable edges. If edges or cleats find their way into your product, it will be detected and rejected by your X-ray or metal-detector.

Read more.

Homogenous belts are one solid pieces of extruded polyurethane or polyester. Because they don’t have layers, fabrics or crevices, they are ultra-hygienic and easier to clean. They can be used for product transfer, trimming, and transfer to pack.

- Soliflex PRO is a homogenous positive drive belt (meaning it’s driven by a unique lug and sprocket system design, offering the ultimate hygiene and tracking). It offers a lower total cost of ownership and excellent product release properties. It comes in blue color for increased food safety and it’s compatible with metal detectable, antimicrobial scrapers (like Ultrascraper) and accessories. Lug positioning is customizable and the belt is also available in a mini version to suit your applications for conveying smaller products.

Read more.

Positive drive conveyor belt system with smooth covers, AMMDrive, works well with Soliflex PRO lug technology, which ensures optimum tracking performance, reduces traction forces and lowers operating costs. The plug & play installation keeps maintenance costs down – no running-in is required. In fruit and vegetable processing, this solution can be utilized in reception and through stages.

Modular belts are belts that are assembled in a bricklay pattern and can be customized to almost any length and width, and from small opening to the most open. They can be straight-running or side-flexing.

- uni BLB is an open belt specifically designed for cooking, steaming and blanching vegetables. It’s perfect for handling sensitive food and vegetable, and its design prevent belt elongation even in high temperatures or boiling water.

- uni MPB and uni S-MPB are suitable for fresh cut process stages and freezing operations. They can be used in low temperature applications.

- uni MPB 20% Open Nub Top, with its round and spread nub top, dynamic open hinges and UltraClean hygienic sprockets has better non-stick properties, deeper sanitation and excellent drainage properties.

- uni SNB M2 is an open belt that increases cooling and drying process efficiency as it offers open area for increased airflow around the product and requires less space for cooling and drying processes.

- uni M-QNB, M-TTB and M-NTB have a smaller pitch suitable for applications needing small transfer gaps.

POPUP flights integrated into MPB modular belt systems. They are mechanical flights that automatically stand when needed, and lie down when they are not. Partnered with discharge belt scraper, this feature effectively saves labor-intensive cleaning up – of both belts and floors – and makes sure that the product for discharge reaches it intended destination.

Read more.

Synthetic conveyor belts are made of fabrics with polymer coating on the top and/or bottom side. They are strong, stable and impact resistant, so in fruit and vegetable processing, they can be used for receiving bunker, inspection, cutting, trimming, and sorting. They offer excellent resistance to oil and fat, good resistant to cleaning agents and come with non-fray, non-shrinkage properties.

- Flexam belts, available in many different hardnesses, profiles and colours have a good mechanical and chemical resistance. They are used mainly for packed foodstuff or dry food and can be used also in trimming stages or infeed lines.

- Nonex belts have good resistance to oil and fat and are food compliance for all foodstuff. They can be used in trimming or infeed lines according to the different applications.

- Ropanyl belts have a polyurethane coating with exceptional resistance to grease, oils and chemicals. They have non-stick properties, and they are hard, smooth and easy to clean. They are mainly used in the cutting steps and in sorting or scanning stages.

- Dectyl are metal detectable belts with polyurethane coating, which is a step forward in food safety on risks of plastic foreign bodies. One version has matt finish for non-stick release properties and the second is glossy in high grip for positioning. They come with Dectyl test cards which allow you to proof detecrability and recognise the minimum detectable belt part size in actual working conditions. Wide range of Dectyl accessories include cleats, ropes, sidewalls, etc.

Read more.

Contact us to choose perfect products for your fruit and vegetable production!

With our years of expertise, we can help improve food safety on your production line. Contact us to choose the best quality products from our portfolio and enhance your food safety standards!