Global

Internacional

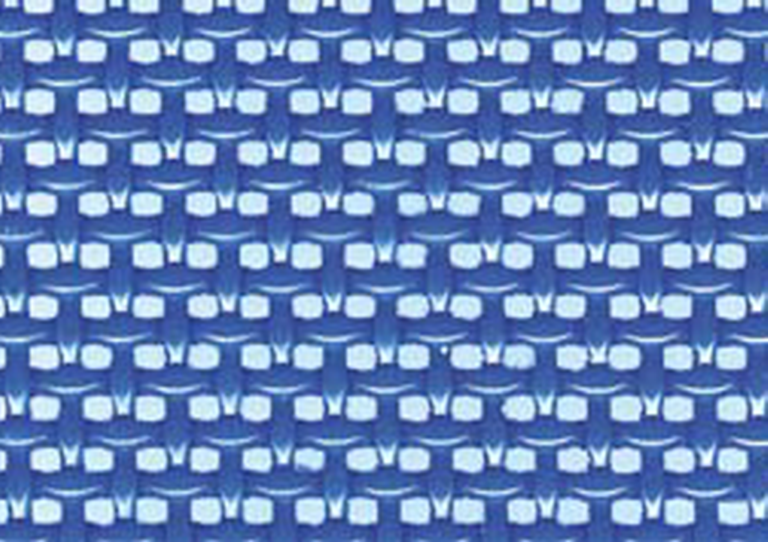

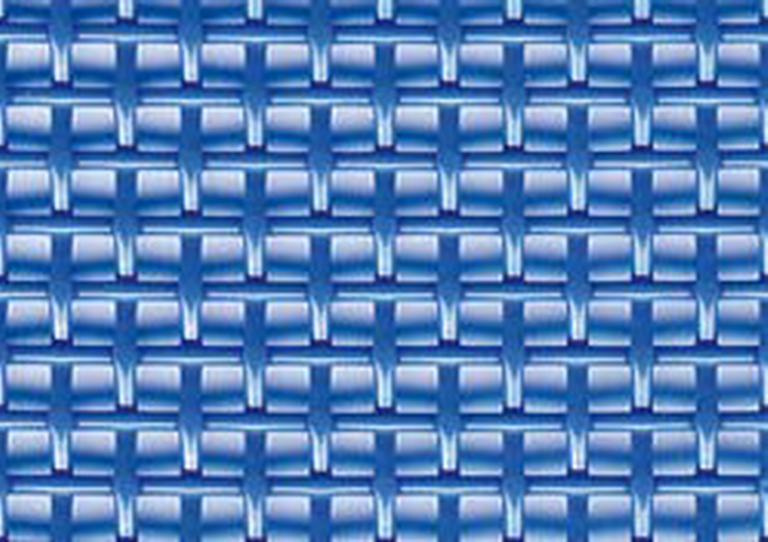

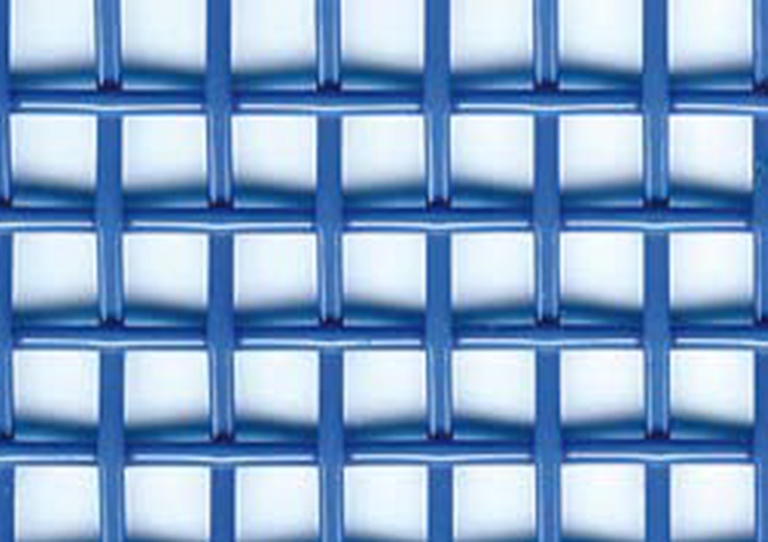

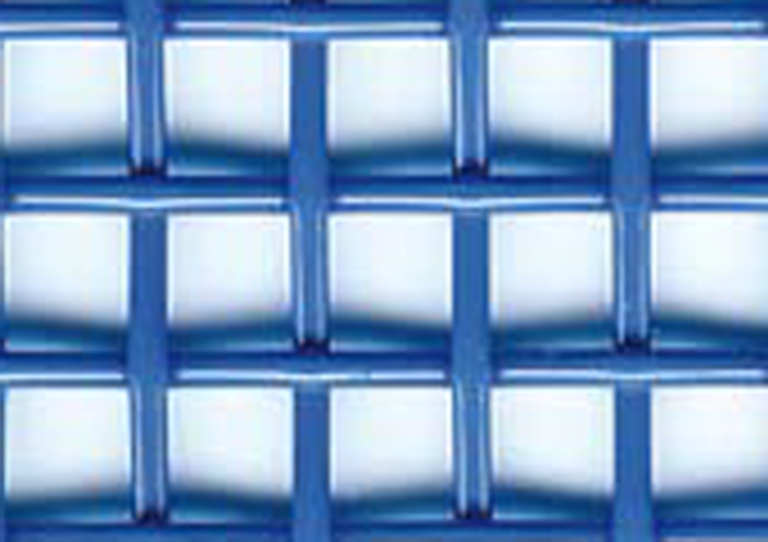

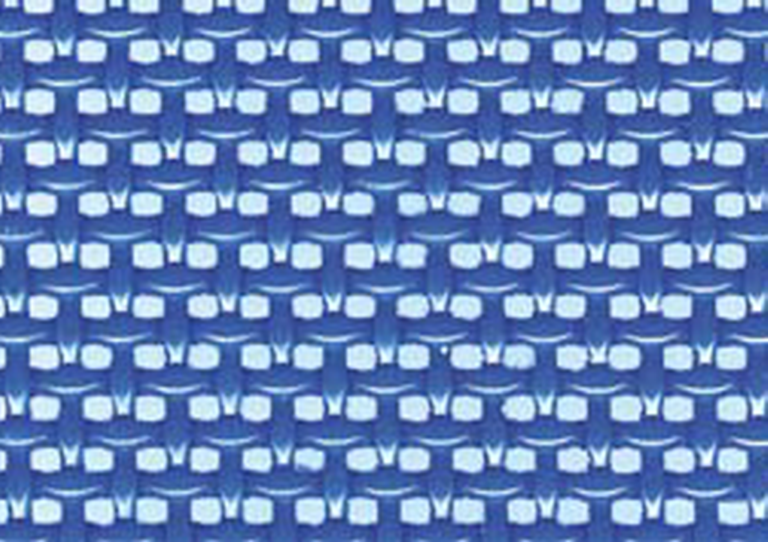

A principal aplicação das Correias Ultrascreen da Ammeraal Beltech consiste na desidratação e secagem de vegetais cortados frescos e lavados. Os diferentes tamanhos da malha do material de filtro permitem obter a solução perfeita para cada produto. Combinado com uma ampla área aberta, resulta num elevado rendimento de produção.

As Correias Ultrascreen também são utilizadas nos processos de arrefecimento, reciclagem de águas de lavagem, tratamento de águas residuais, filtragem, peneiração e compressão.

Benefícios:

*Dependendo do tamanho da malha

*Dependendo do tamanho da malha

*Dependendo do tamanho da malha

*Dependendo do tamanho da malha

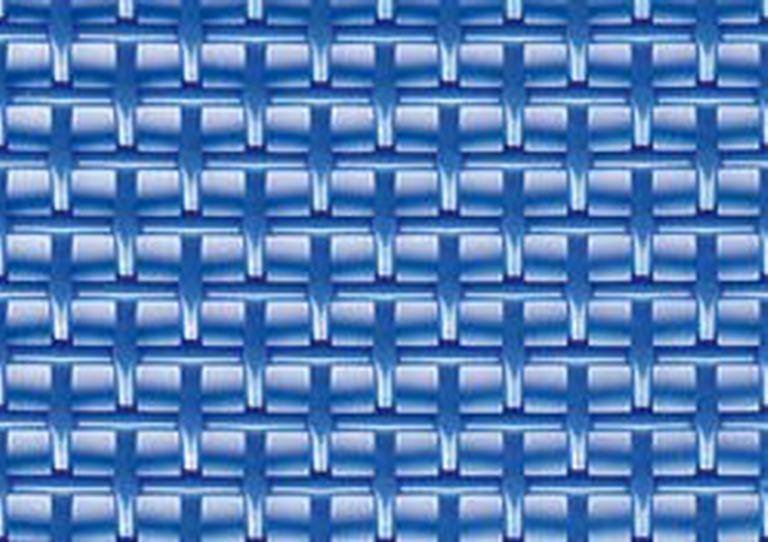

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Os produtos de destaque são apenas um subconjunto da nossa extensa gama de produtos, a mais vasta do mercado. Os nossos especialistas poderão ajudá-lo a encontrar a correia certa. Preencha o formulário de contacto ou visite a nossa página de contacto.

*Consulte o seu especialista local Ammeraal Beltech para determinar o tipo, cor e combinação de material de correia mais adequados aos seus requisitos específicos e a disponibilidade de stock local.