Global

Internacional

Our planet is the most valuable asset. We know this, and that is why we are using the recycling technology to revolutionise the world of belting as we know it. We’re leading the way to launch the production of conveyor belts with fabrics obtained from PET bottles.

With recycled fabrics, we introduce the opportunity to run your business in a more sustainable way, supporting the well-being of the planet. What’s more, we aim to introduce this technology to every industry and application.

PET bottles are not a waste anymore. They’re the potential to thrive on - for your business and the Earth.

Recycled fabrics incorporated into the belt’s structure originated because we were looking for a way to run business in a more sustainable way, and at the same time to empower our customers to do the same.

Ammeraal Beltech is a part of AMMEGA Group, which is a signatory of the United Nations Global Compact and adheres to the following objectives:

You may read more about our environmental policy here.

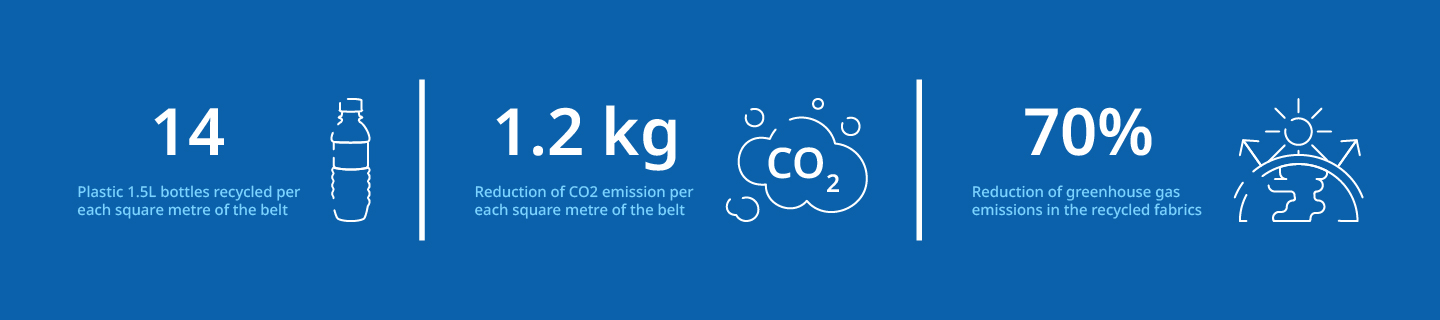

Until now, the production of fabrics for belts has required the use of virgin polyester. We are now able to replace it with a much more environmentally friendly solution - recycled polyester. The process involves the collection of PET bottles and turning them into fabrics, which can be next interwoven into the structure of the belts. Such a procedure significantly reduces carbon dioxide emissions and requires less water and energy.

This is a great opportunity to improve your environmental score and operational sustainability. You’ll contribute to the reduction of pollution, which further benefits health, personal satisfaction and brand reputation.

Sustainable companies are better perceived by investors. Higher ratings in sustainability indexes may increase the value of your business. Conscious entrepreneurs focus on social and environmental factors when evaluating their investment choices. They may rely on such ratings as MSCI KLD 400 Social Index, Dow Jones Sustainability Indices, FTSE4Good Index Series. Highlight your presence there.

With sustainable solutions, you may also apply for ISO or ANSI certification in this respect. Such a verification enables you to serve companies which make these standards a must-have, thus may increase your sales and revenue. Certifications help your business to be transparent and follow the best practices of limiting impacts.

Recycled polyester material has outstanding features and is as efficient as virgin one. It remains strong and stable even under high loads and temperatures. Belts with recycled fabrics will not compromise the quality of performance and will enable you to be sustainable. They provide safety and environmental impact reduction.

Be trusted for your choices and attitude towards natural resources. Create positive PR and marketing. Encourage partners to follow in your footsteps and improve the environment together.

| Improve your sustainability score | Achieve highly efficient and sustainable performance | Build a strong brand reputation |

|

A great opportunity to improve your environmental score and operational sustainability. You’ll contribute to the reduction of pollution. |

Recycled polyester material has outstanding features and is as efficient as virgin one. |

Be trusted for your choices and attitude towards natural resources.

|

Imagine a mountain of rubbish and a seashore littered with waste. That’s a direct threat to all living creatures. Because we understand this, we try to recover as many secondary raw materials as possible.

After being discarded by consumers into appropriate containers, PET bottles are collected and taken to a recycling plant, where they are sorted by type and colour.

Bottles are stripped of their labels and caps, cleaned, crushed and shredded into small flakes, which are later melted and turned into pellets.

The pellets are further melted and extruded into fiber, which is crimped, cut, drawn, stretched, and finally - baled.

The baled fiber is then transformed into fabric rolls - ready to be transported to our plants. There, they are further processed and incorporated into Ammeraal Beltech product range.

As you can see, belts with recycled fabrics can benefit both our planet and your business. Join us in our mission to make the Earth a cleaner place through sustainable belting solutions. Together, we can design eco-friendly conveyors that respond to your specific application.