Global

International

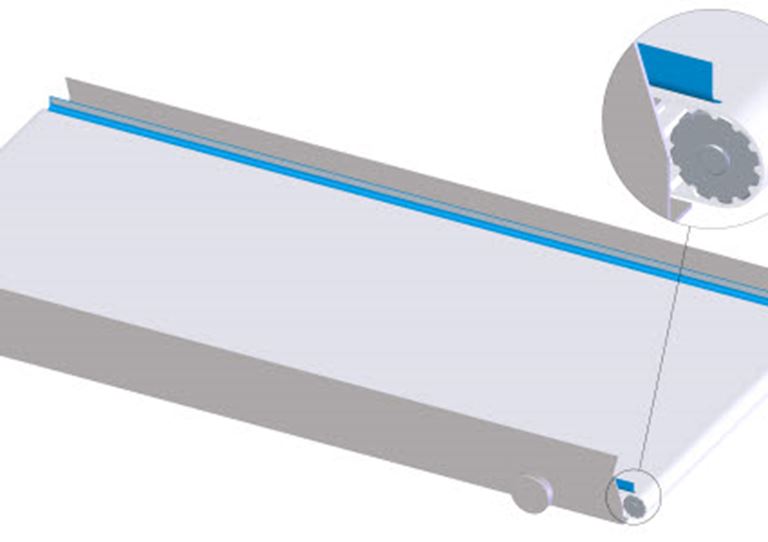

Ammeraal Beltech’s Ultrasync Belts are synchronous and driven by a standard T10 sprocket with a pitch of 10 mm. Available up to 1000 mm wide.

Ultrasync Benefits & Features per Industry Application:

Food industry

|

Hygiene paper production |

Tyre building |

|

|

Thermoplastic polyurethane

A durable and easy clean plastic. The thermoplastic properties allow for an embossed belt surface as well as welded accessories.

For slip free conveying (even if the belt / conveyor is polluted with fat, moisture, dough or flour).

Industries / applications:

Thermoplastic polyester

UC5300: This belt offers excellent chemical resistance.

Industries / applications:

Ammeraal Beltech's brand name for silicone is SILAM

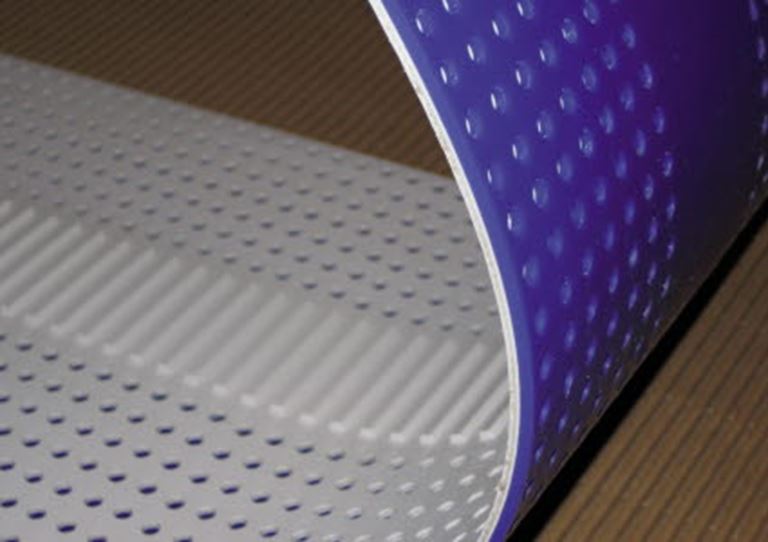

Often used in combination with vacuum to keep a product in place. This in combination with the positive drive of the belt enables the user to know exactly where the product is at all times.

Industries / applications:

Polyamid fabric topside

This low friction fabric allows for:

Industries / Applications:

Featured Products are only a sub-set of our extensive product line-up, the widest in the business. Our experts can help you find the right belt. Fill-in the contact form or go to our Contact page.

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.