Global

International

Primary processing belts need to be hard-wearing and highly resistant to casing and flavouring liquids. They should also be low noise, easy to clean and deliver a long service life.

At Ammeraal Beltech, we have belts with all these characteristics and more; belts with high friction and low friction coefficients, with profiled surfaces, with operating angles of up to 40°, able to trough and with the high lateral flexibility to prevent tobacco dust from spilling.

Explore using the drop-down menu or by clicking on the pointers

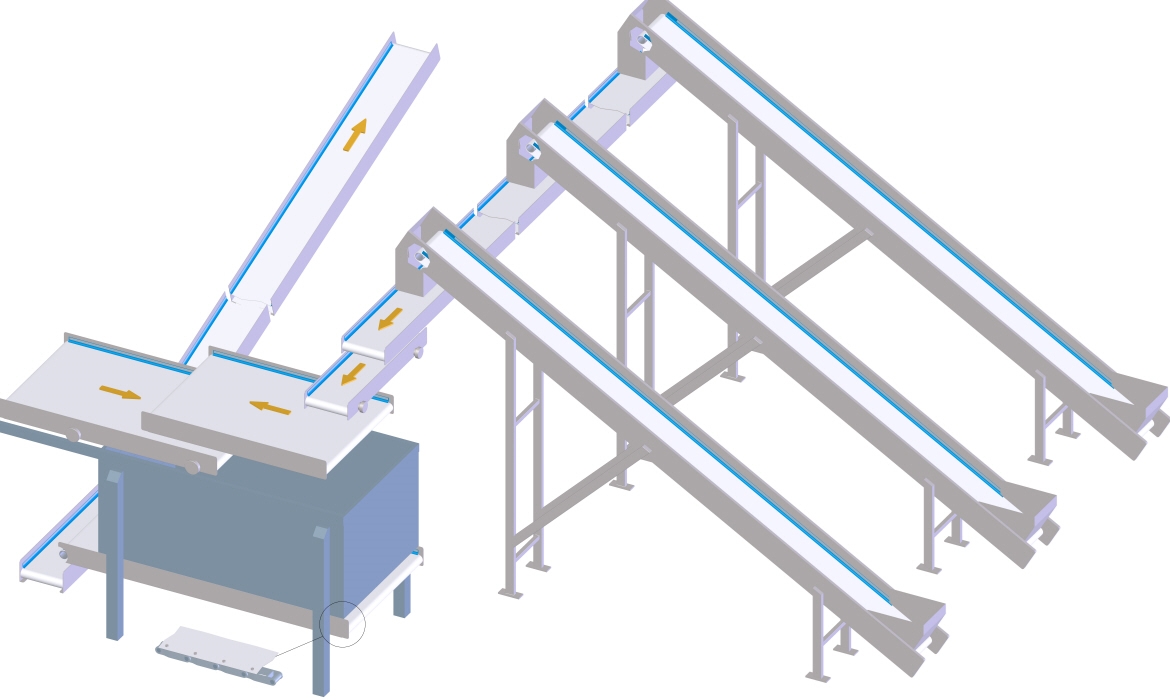

This infographic is used as a general indicative example only.

Actual factory and process configurations could vary, but our industry experts know them all.

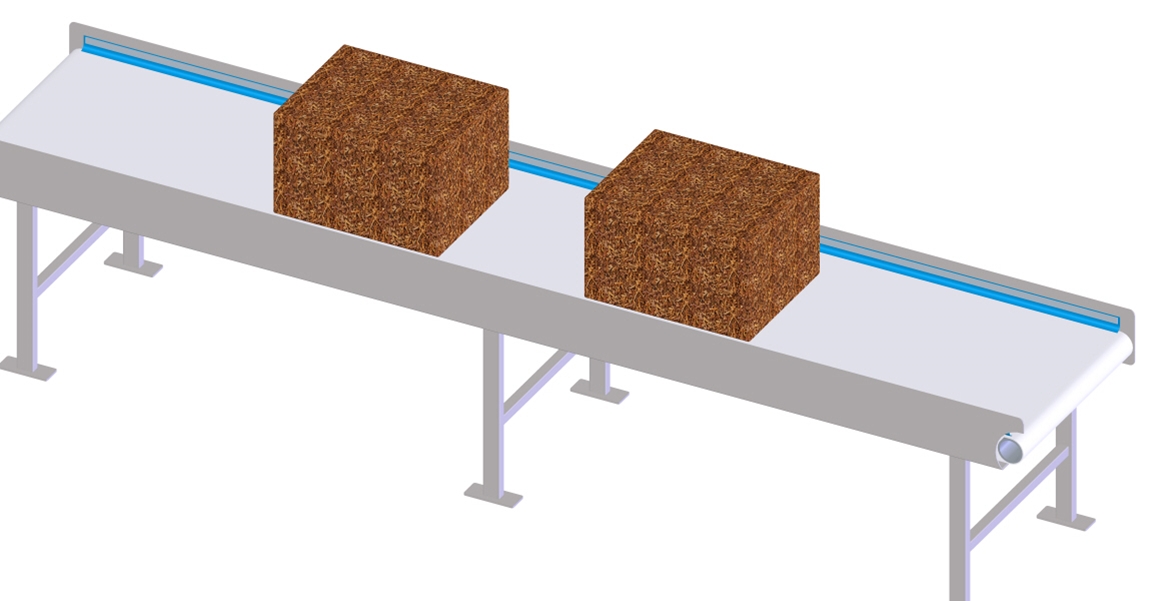

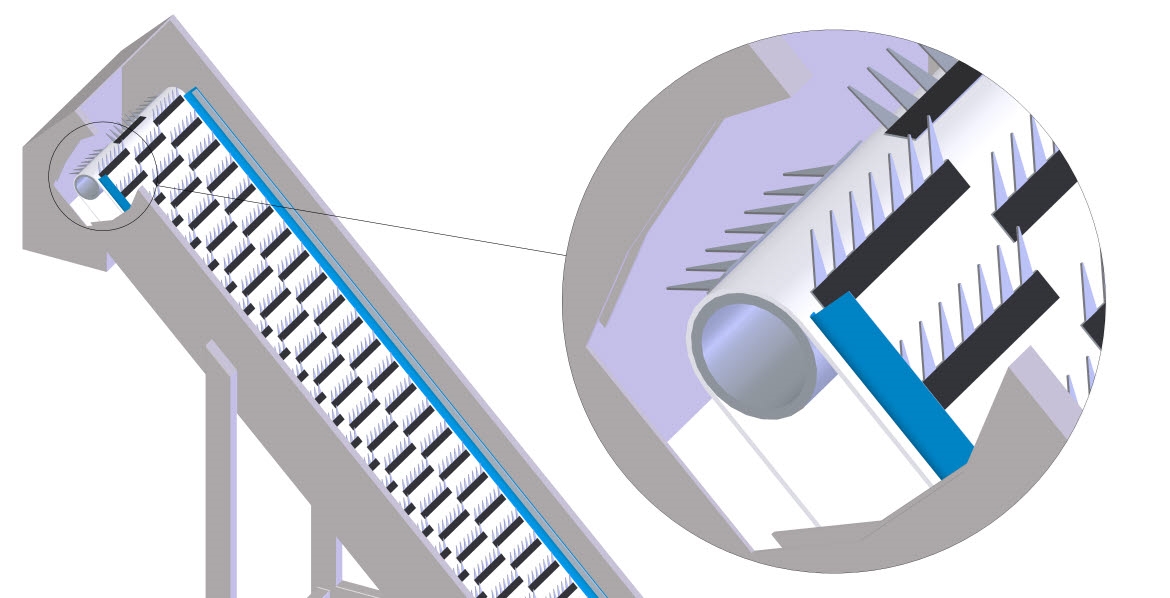

For this process, belts need to be impact-resistant and have the right friction coefficients to keep the dry tobacco blocks in place on the belt surface.

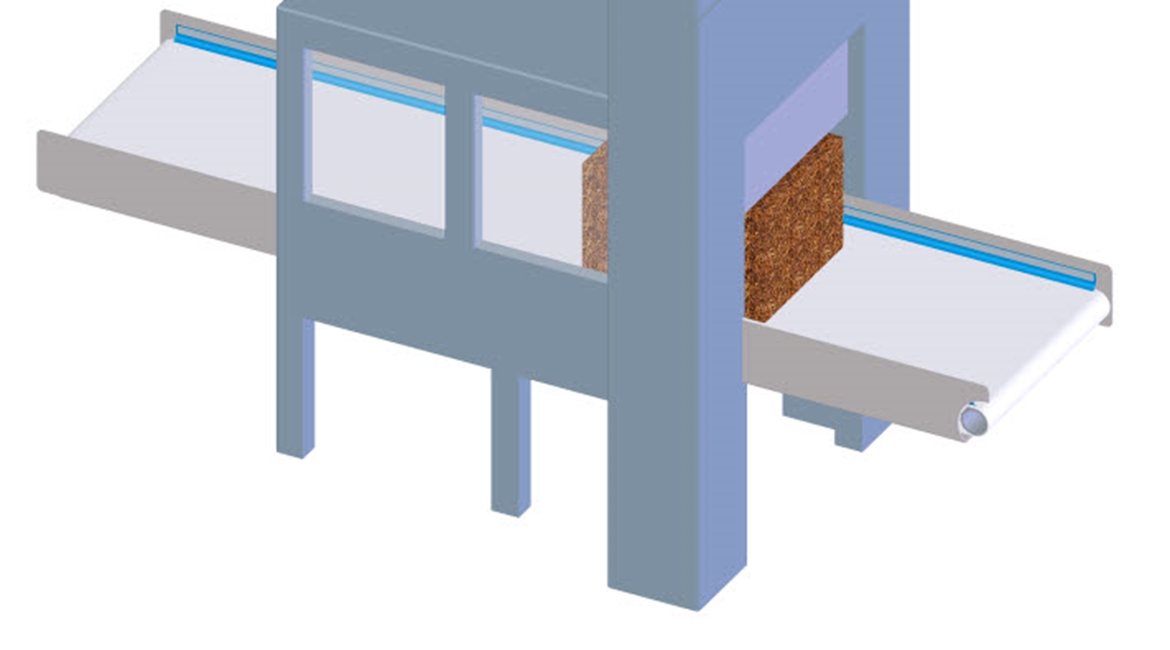

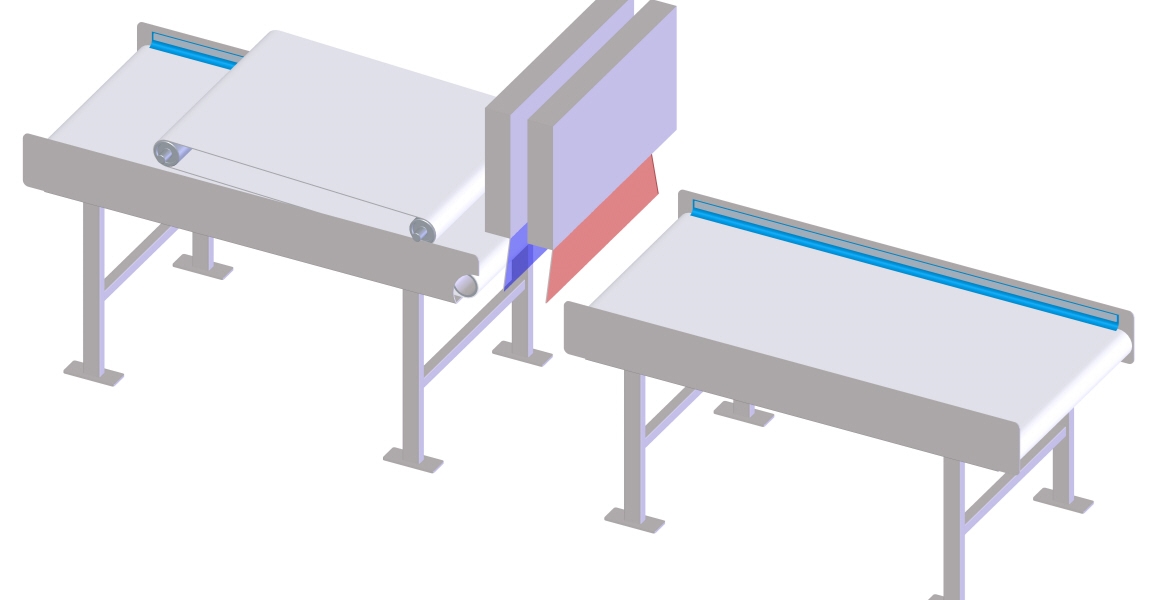

Big tobacco blocks are cut into slices by an automated guillotine system. This operation may take place on a belt or it may occur between two belts.

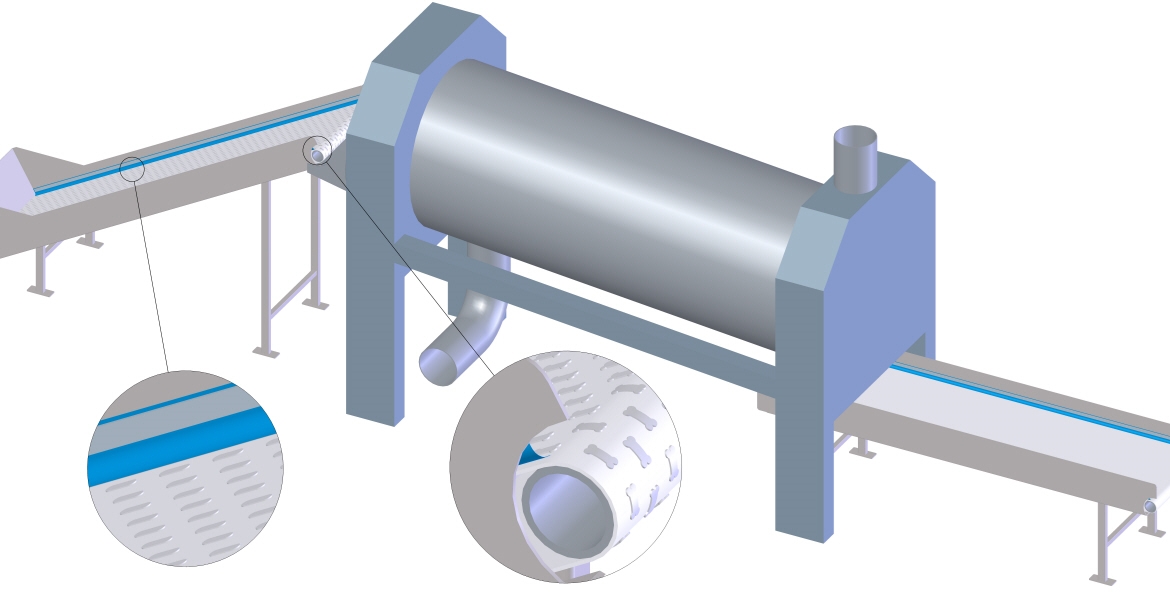

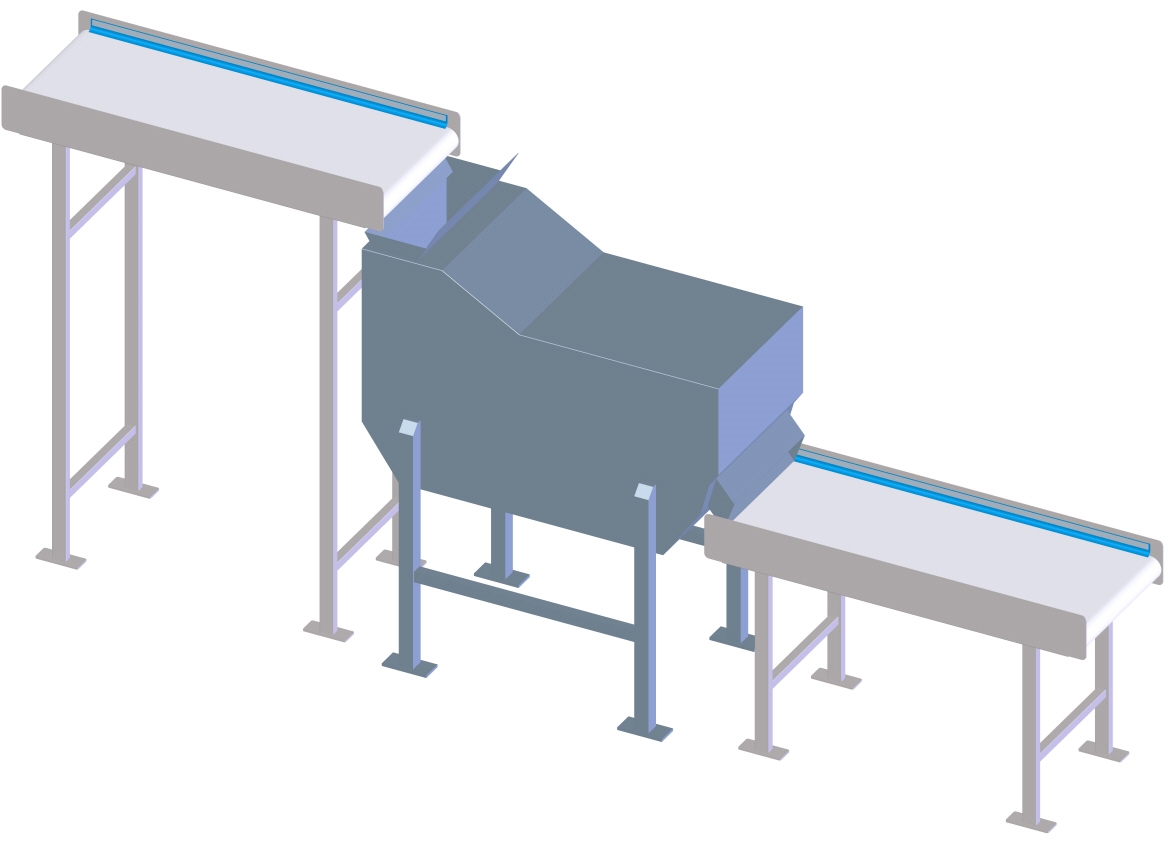

In this step, the slices are taken on incline conveyors to the first DCC (Drum Condition Cylinder). Here the brittle leaves are treated with heat and steam to make them flexible again. Additional fluids (to add flavours) may also be present.

During Green Leaf Processing, NTM (Non-Tobacco Material) has already been manually removed. In Primary Processing, companies are using high-tech scanner equipment for the smallest bits. Detection is based on differences in material structure and colour.

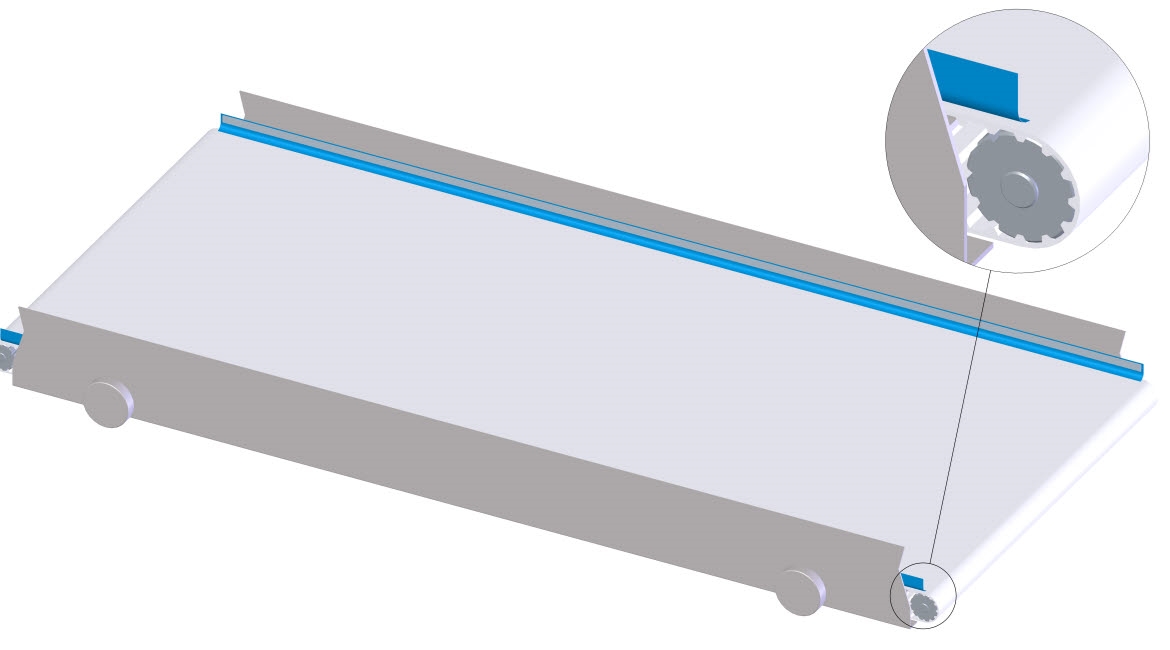

The feeder belt is used to carry the tobacco to the blending silo conveyors.

The mixing of different types of tobacco according to precise recipes to produce a characteristic, homogeneous blend.

Blended tobacco is cut into fine strands. During this step, a significant amount of tobacco fluids are released from the leaves.

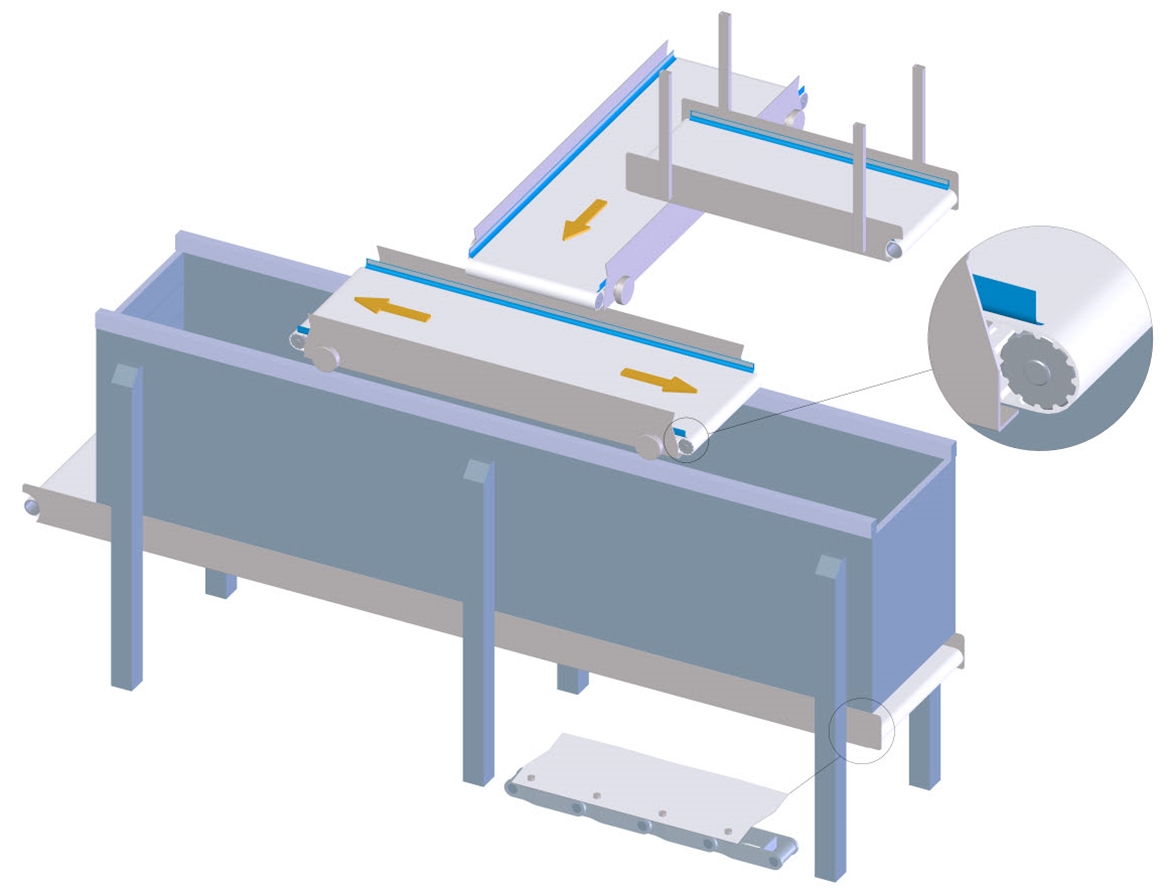

For this application, a proper belting system design is paramount: the belt runs bi-directionally on a rail system.

The final step for Primary Processing is storing the cut tobacco in silos, which can be either drum-driven or chain-driven. All the silos run very slowly and the lifetime of these belts is long (10+ years).

Throughout Primary Processing, conveyors have tobacco-proof side skirt material (to avoid tobacco ending up between the belt and the conveyor) and curtains (to avoid pollution).

*Recommended Products are some examples of our solutions in a specific process. Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.

By continuing to browse our website you agree to our use of cookies and Privacy Policy. More information about cookies.