Globální

Mezinárodní

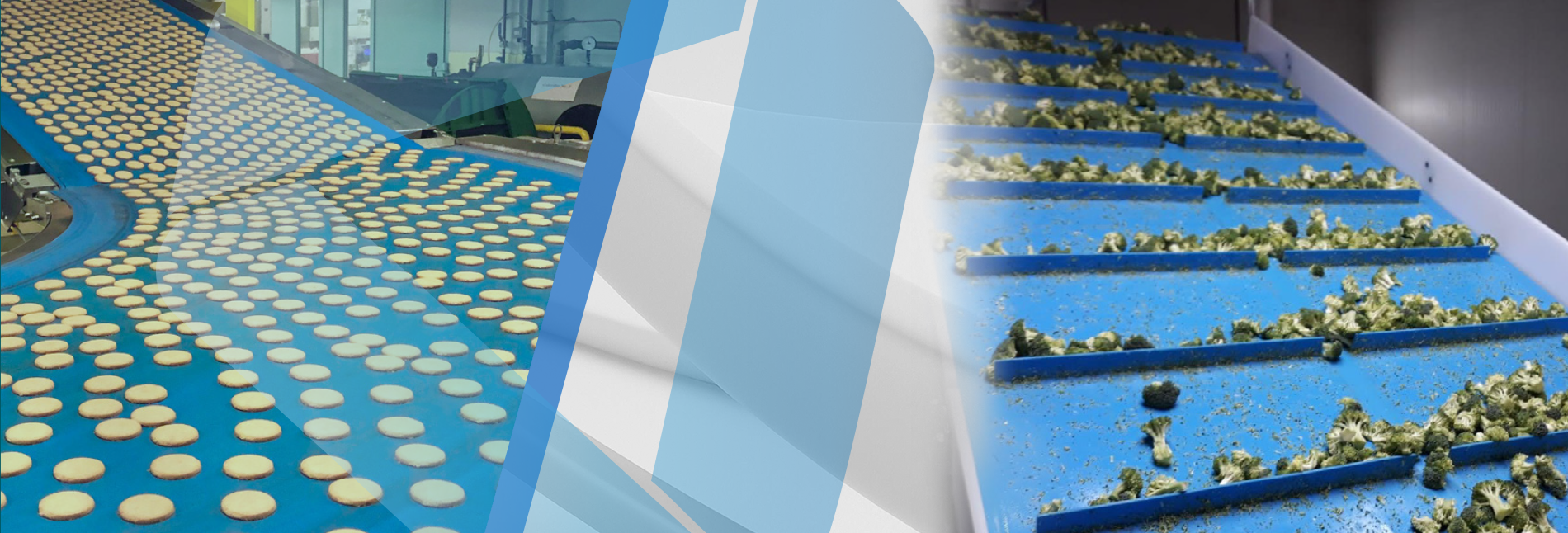

We’re excited to announce that we are expanding the Dectyl range with Dectyl XMD, our next step forward in food safety on risks of foreign bodies.

With Dectyl XMD, you’ll be able to detect any of its broken fragments with X-ray and metal detectors. That’s what we call a dual detectable solution.

Why Dectyl XMD belts are a game-changer in food production

The Dectyl XMD synthetic belt acts like insurance for your production line. It is designed to detect broken belt fragments with proven sensitivity control, helping you safeguard both your brand reputation and consumer safety.

With Dectyl XMD, food manufacturers gain a powerful ally in the fight against contamination. This innovative belting solution offers:

Validate safety with Dectyl XMD test cards

To ensure detection performance in your specific production setup, we provide Dectyl XMD Test Cards. These allow you to test and validate the minimum detectable size of Dectyl belt fragments within your own food processing line.

What‘s the smallest belt fragment that can be detected? Minimum size depends on many factors such as type of contaminants or X-ray equipment detector, belt speed, vibrations, humidity, food product, fragment shape and position; that is why there is no industry standard, which makes Ammeraal Beltech Dectyl XMD test cards unique.

Customized and accessorized for your needs

The Dectyl XMD range includes two surface finishes to suit different conveying needs:

You can also pair your belts with dual detectable accessories, including:

Set higher standards in food safety

Act proactive with Dectyl XMD! Avoid product recalls and ensure food safety.

Contact our team to learn how Dectyl XMD can be tailored to your production line needs. Take the next step toward contamination-free food processing.