Globálny

Medzinárodný

08-03-2023

In this article piece, we shall take a closer look at the world-wide phenomenon of PET plastic. Poly-ethylene terephthalate (PET), more commonly known as polyester, is a strong and light type of plastic that redefined convenience. Today, we use PET throughout all industries, starting with clothing fabrics and cushion inserts, through automotive parts and accessories up to a more recent development, namely Ammeraal Beltech’s conveyor belts with rPET Fabrics. However, the world-changing PET revolution began a few decades ago in the Food Industry.

PET Bottles Industry

Polyester, as a packaging for food and beverages, provides a solid and cheap cover. It is a perfect material to produce yogurt containers, clamshells for fragile salad dressings, but most importantly, liquid bottles. Despite plastic being used in the Food Industry since the 1950s, it was the invention of Nathaniel C. Wyeth, the Poly-ethylene terephthalate, that marked the popularity breaking point. He aimed at bottling soda water in plastic, as the pressurised liquids were too strong for the usual material. PET bottles became in demand in the 1970s when Beverage Industry leaders realised that the new kind of plastic had been approved by Food Safety authorities, thus enabling massive expenditure savings along the whole supply chain. When compared to glass or aluminium counterparts used for sparkling drinks, from raw materials cost, through easier moulding and casting, to safer transporting and storing, PET containers quickly became triumphal.

Marketing the new solution was unchallenging. In 1978, Coca-Cola and PEPSI introduced the world’s first PET bottle of 2 litres volume, making it accessible globally almost instantly. The biggest influence, though, came in the late 1980s in New York. Famous American supermodels started to promote Evian sparkling water bottles as a convenience article that should always be at hand. Physicians claimed that the water bottle is nutritious for hair and skin, and that it is healthier to drink than tap water and soda drinks. Additionally, polyester was said to be entirely recyclable, which legitimised its use completely.

People showed an instant appreciation for the lighter, cheaper and reusable containers. Suddenly, anyone could take a small water bottle for a walk, or a bike ride without worrying about damaging it or not being able to close it again. Polyester was rising in other areas simultaneously. Organising kitchen essentials became easier thanks to strong transparent boxes that wouldn’t break if dropped. Furthermore, groceries stopped being so weighty in shopping bags. Produced constantly, polyester became an irreversible part of the civilisation.

Consequences

A few decades later, a problem emerged. It turned out that the pace of PET recycling practices was too slow to cover the ever-increasing amount of worldwide PET manufacture. Not to mention the impact of the huge percentage of people who were indifferent to the reprocessing of plastics.

The repercussions of those times can be felt today as our planet hurts from the surplus of PET bottles piling at seashores, polluting soil, and affecting the animal world.

New legislations are signed to stop the plastic pollution and to improve the environmental impact of manufacturing businesses. Selected economic zones have already banned the use of plastic bags. If the polyester surplus is not resolved, likewise the PET bottles shall be prohibited. However, in such an event, all the PET benefits would disappear from our lives as well.

Start recycling

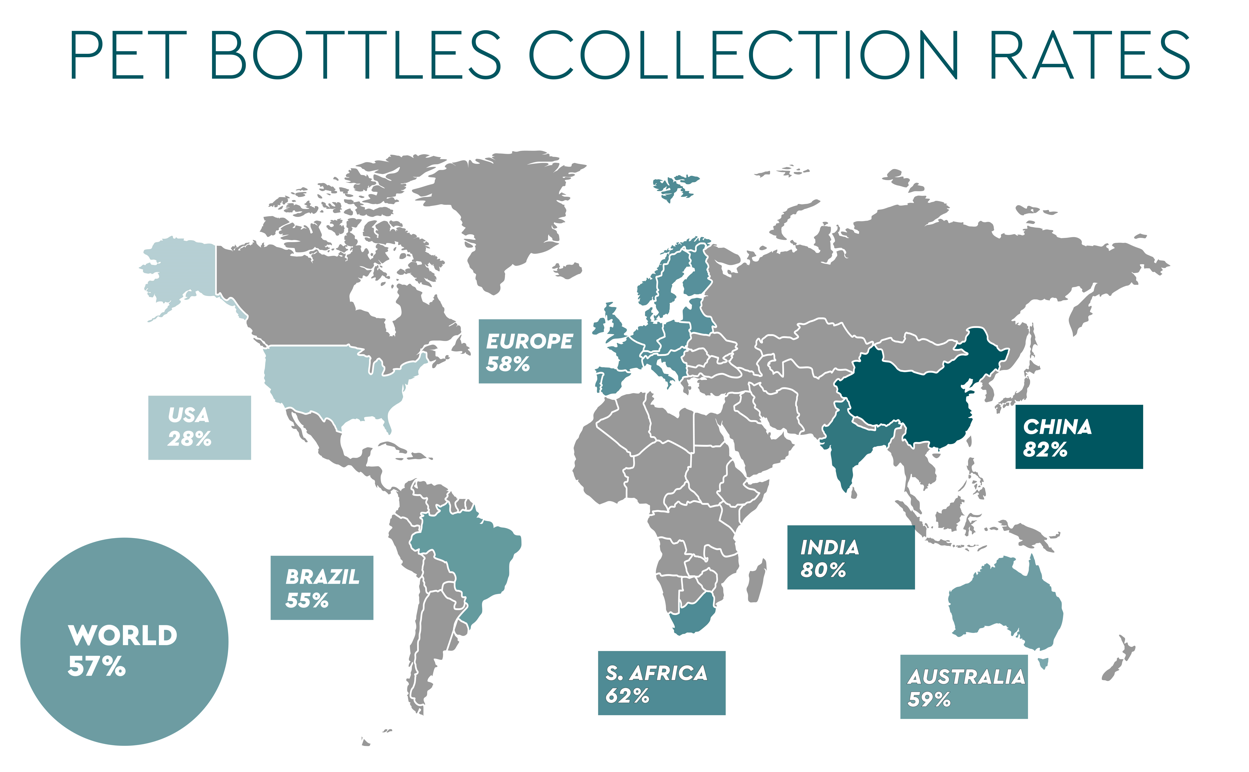

Solving the existing PET pollution problem requires all societies to act. Unfortunately, in 2021, only 15% of the total polyester fibres were reprocessed, which means 85% ended up in landfills or in the oceans. For this reason, Ammeraal Beltech spreads recycling policies and initiatives to neighbouring manufacturers and producers. For a contrast, the recycling pioneer is Norway, as it collects up to 97% of PET bottles, Europe reprocesses over a half collectively, whereas the USA achieves less than 30%.

When it comes to the recycled Polyethylene terephthalate (rPET), it is often converted into fabrics. To be more precise, when a plastic bottle is put into a proper rubbish bin, it is shredded into small flakes and afterwards either re-bottled as a fully renewable liquid container or moulded as a building material.

Opportunity ahead

At Ammeraal Beltech, we care deeply about limiting carbon footprint throughout industries. Our Global Innovation Manager, Franck Baradel, sees the opportunity lying ahead:

‘The enormous potential for the belting industry is clearly proven by the recent spike in PET recycling volumes. Higher use of recycled PET promotes a more sustainable economy by lowering waste and conserving resources. We strongly believe that the introduction of recycled PET fibres to Ammeraal Beltech is a step in the right direction for us. What’s astonishing is that after only a few months, we have already seen a positive response from our customers and industrial community. It plainly emphasises the need for further innovation and investment in this area to realise its full potential.’

Thus, along with our energy and water saving solutions, we have launched the Belts with Recycled Fabrics initiative. The concept uses rPET fibres as a compound of our products. Our findings established that there is no efficiency difference between the use of virgin polyester and the recycled one. We save exactly 14 bottles of 1,5L volume and 1.2 kg of CO2 emissions with every square meter of produced belt! This allows us to lead the way for our closest business partners towards more environmentally friendly industries and operational practices.