Global

Kansainvälinen

AMMdrive are positive driven fabric belts, driven by means of drive lugs and sprockets. The innovative PRO lug concept allows the belt to self-track in two cooperative manners:

AMMdrive are positive driven fabric belts, driven by means of drive lugs and sprockets. The innovative PRO lug concept allows the belt to self-track in two cooperative manners:

AMMdrive PRO lug technology combines the advantages of all major belting types in one high-performance solution.

Compared to:

A perfect choice for both new conveyor designs and retrofitting existing production lines.

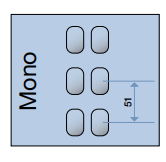

A single-row lug configuration ideal for compact, lightweight conveyors. It provides simple and reliable tracking where space is limited and loads are light.

Advised for belt widths between 80–120 mm.

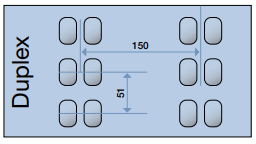

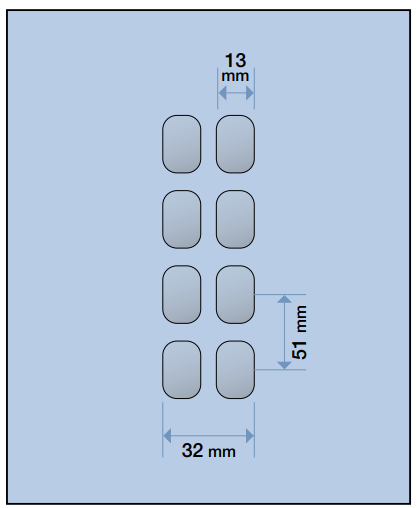

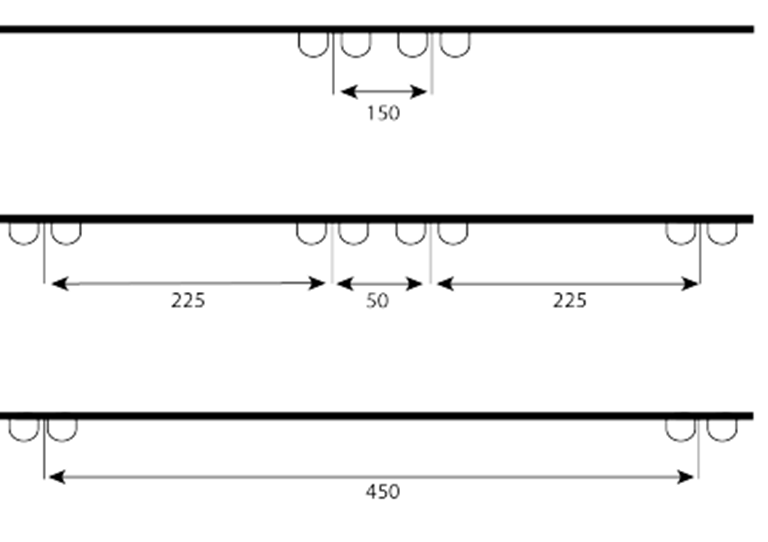

A two-row lug setup and the most widely used configuration. It offers balanced tracking and drive performance across most medium-duty applications and is suitable for a broad range of industries.

Advised for belt widths between 200–500 mm.

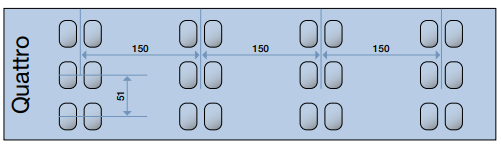

With four rows of lugs, Quattro is ideal for wider belts needing enhanced strength and lateral stability. It’s well suited for larger conveyors with higher loads and throughput.

Advised for belt widths between 500–1200 mm.

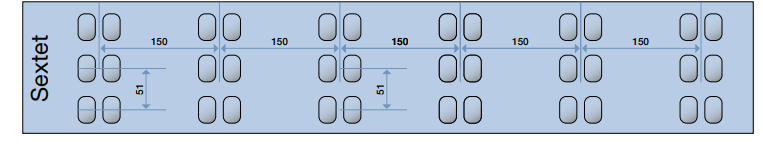

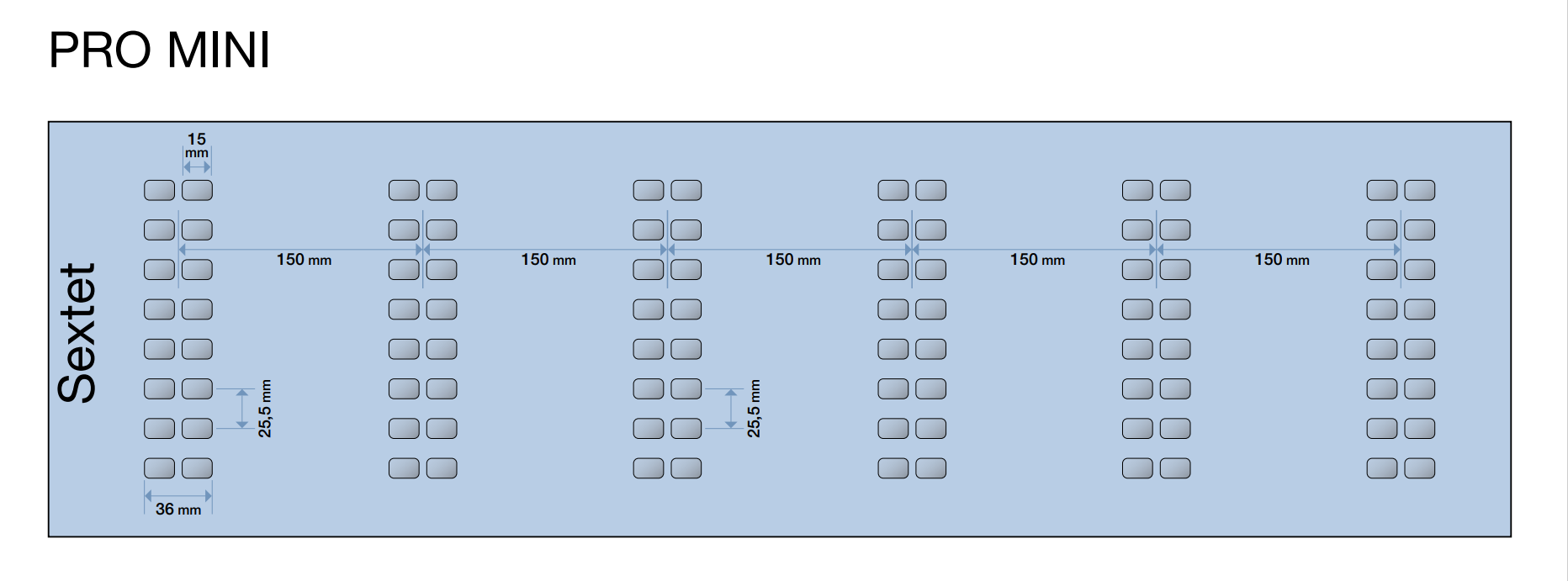

Engineered for maximum tracking control and strength, Sextet is built for ultra-wide belts in demanding, heavy-duty environments.

Advised for belt widths between 1200–2000 mm.

Note: Sextet availability is limited in some regions. Belts over 1500 mm may not be available in all markets.

Delivers all the benefits of AMMdrive PRO while featuring a compact pitch, enabling:

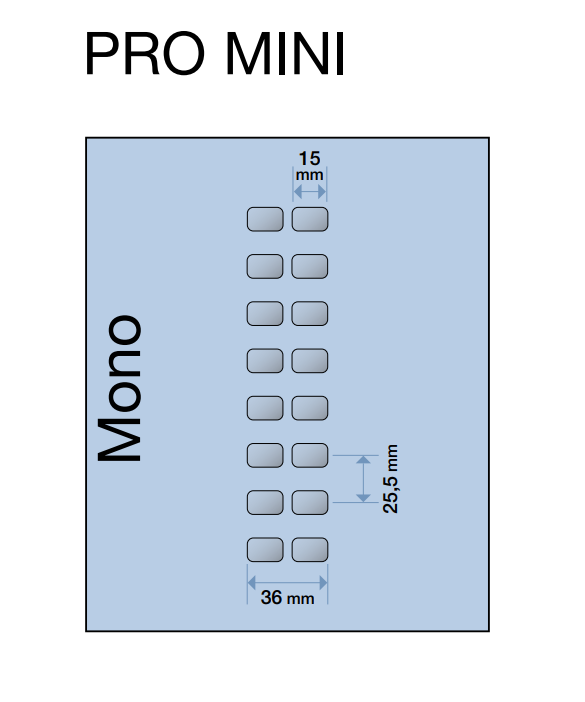

A lightweight single-row lug configuration ideal for narrow belts and tight conveyor layouts. Perfect for compact systems with small pulley diameters.

Advised for belt widths between 80–120 mm.

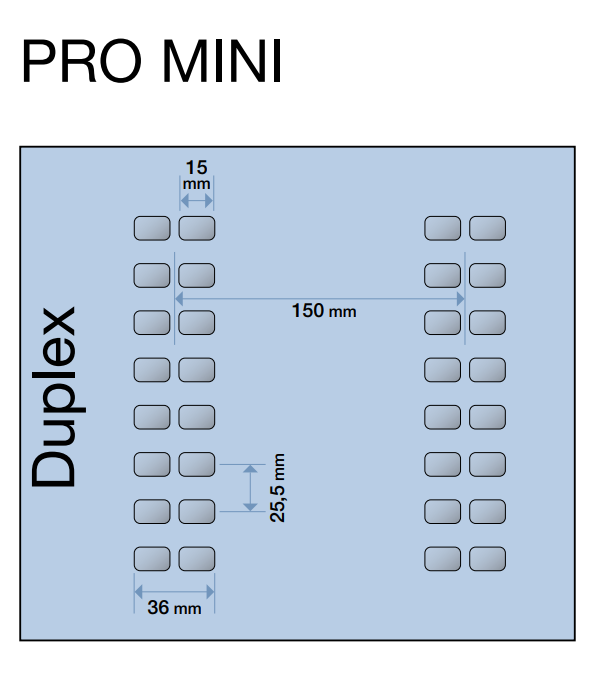

The most common setup, Duplex balances strength and flexibility for medium-width belts. It’s versatile enough to handle a wide range of applications, even in space-restricted environments.

Advised for belt widths between 100–500 mm.

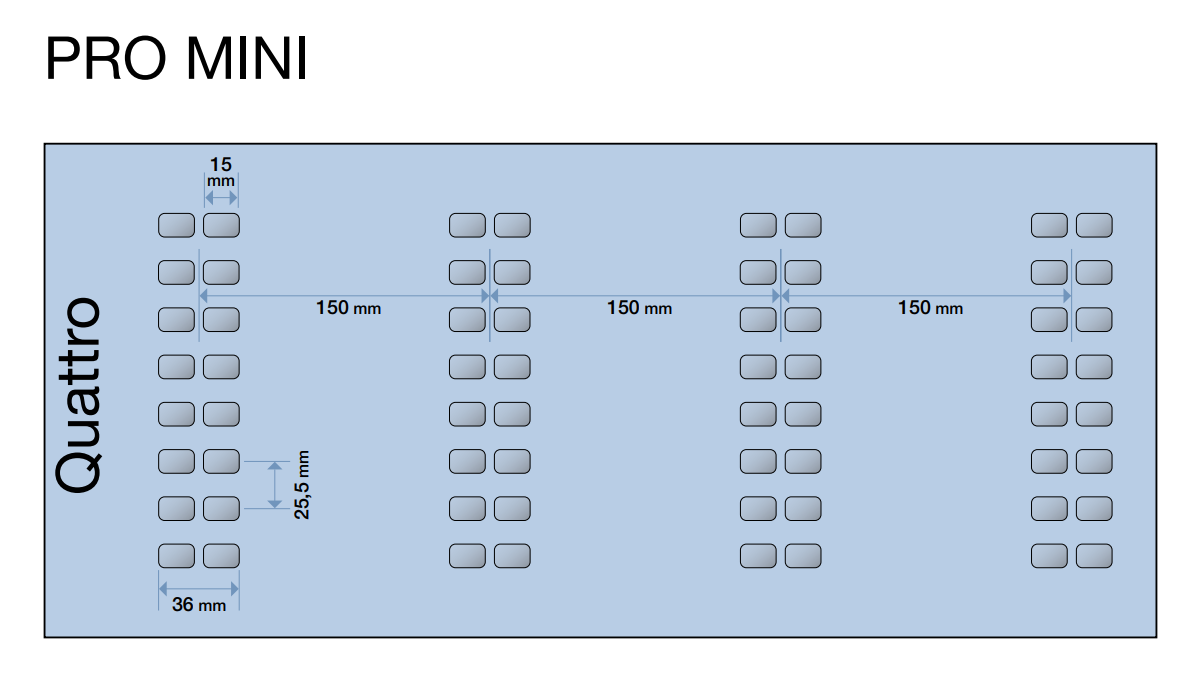

Quattro provides excellent tracking and support for wider conveyors where precision and hygiene are essential. Ideal for mid- to large-scale lines requiring compact drives.

Advised for belt widths between 500–1200 mm.

With six rows of lugs, Sextet delivers top-tier tracking stability for the broadest belts in compact systems.

Advised for belt widths between 1200–2000 mm.

While standard configurations like Mono, Duplex, Quattro, and Sextet cover most applications, some conveying systems demand a more customized approach. That’s where non-standard lug configurations come into play.

Available in both PRO and PRO Mini versions, these custom-made setups are developed in close cooperation with our technical team. With AMMdrive, your conveyor isn’t limited by standard – it’s empowered by custom.

Belt tracking has challenged maintenance teams since conveyors were first used. Traditional solutions – like belt guides, snub rollers, or crowned pulleys – are often expensive and ineffective. AMMdrive PRO lug technology ensures flawless belt tracking through two self-reinforcing mechanisms: