Global

Internacional

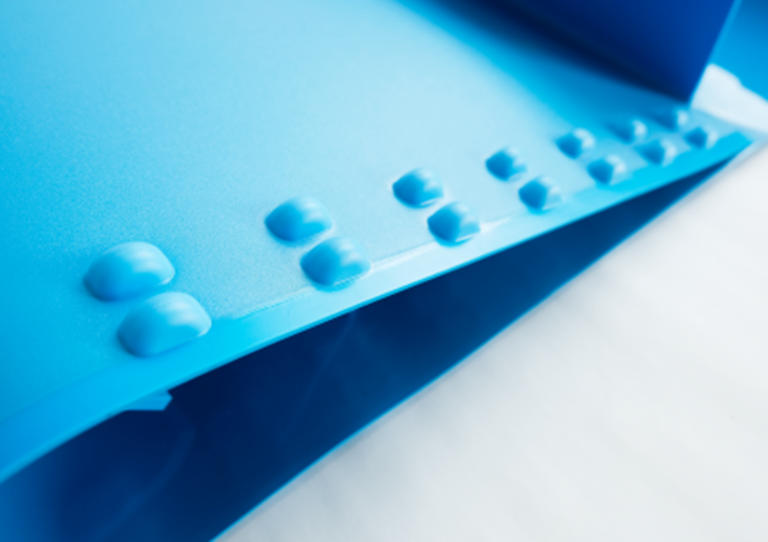

AMMdrive belts are produced in different materials (PVC, TPU & TPE), thicknesses, colors and with different features. Therefore, each belts represents unique specification tailored for the need of your conveyor and application.

AMMdrive belts are produced in different materials (PVC, TPU & TPE), thicknesses, colors and with different features. Therefore, each belts represents unique specification tailored for the need of your conveyor and application.

AMMdrive belts made with TPU (thermoplastic polyurethane) deliver an excellent balance of flexibility and durability, making them a reliable choice for many demanding applications. They’re ideal where hygiene, oil resistance, and abrasion protection are essential.

With a working temperature range from -20 °C to +90 °C, TPU belts stay stable and efficient in both cold and warm environments. This material is a solid performer across a wide variety of food-grade processes and industrial uses.

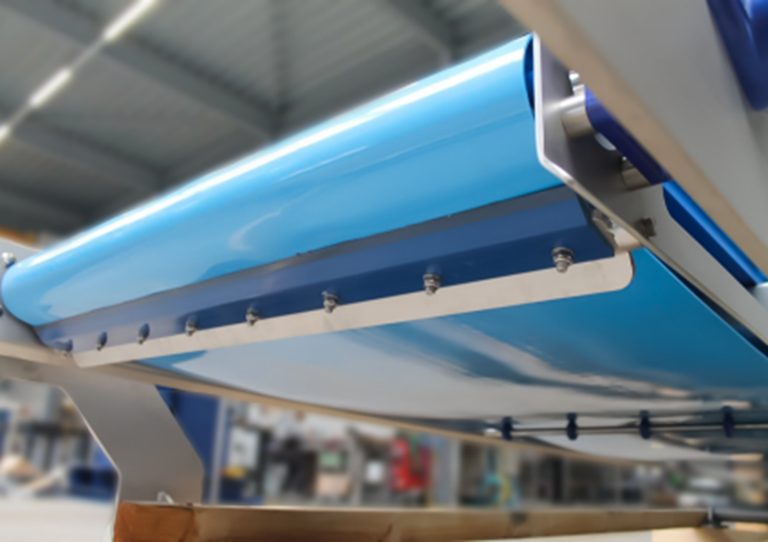

AMMdrive U belts made with TPU (thermoplastic polyurethane) are the go-to solution for demanding food-grade applications where hygiene, mechanical durability, and tracking reliability are essential. Available in light blue and white, these belts are fully food-grade, with a sealed, encapsulated construction for optimal sanitation.

Key features:

The self-tracking design of AMMdrive U eliminates the most common cause of belt failure in traditional friction-driven systems: misalignment. By avoiding tracking issues, these belts help reduce unplanned downtime, minimize belt replacement frequency, and lower maintenance costs – delivering a reliable, cost-efficient alternative to solid homogeneous belts.

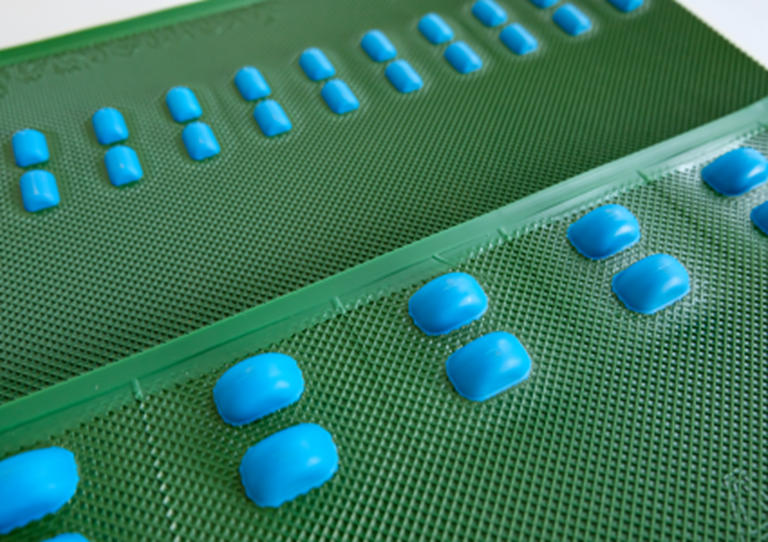

AMMdrive belts with TPE (Thermoplastic Elastomer) are built to handle tough environments where heat, chemicals, and mechanical stress play a role.

With temperature resistance up to +110 °C, they also maintain excellent stability in sub-zero conditions – staying flexible, crack-resistant, and mechanically sound without becoming brittle.

TPE belts are ideal for applications requiring high product temperature and aggressive cleaning routines. Thanks to their hard top layer, thicker 2-ply versions offer outstanding mechanical strength and long-lasting durability.

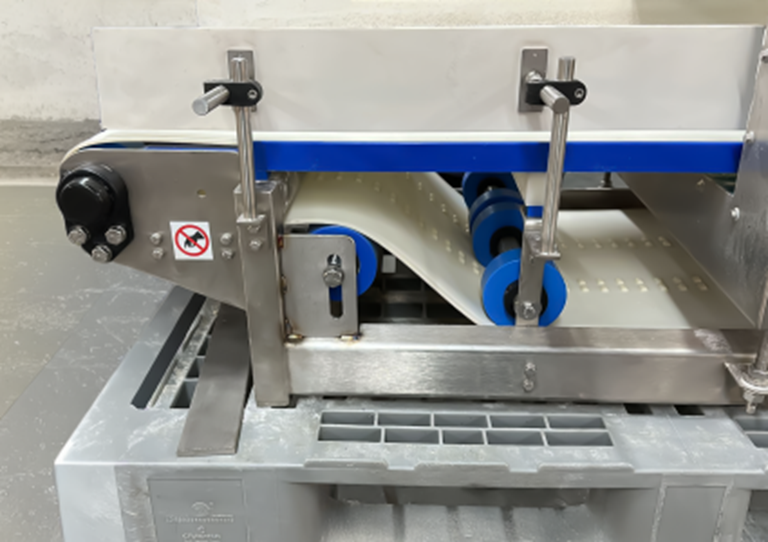

AMMdrive E belts made with TPE (thermoplastic elastomer) are built for demanding conditions that combine thermal extremes, chemical exposure, and mechanical wear. Available in both 1-ply and 2-ply constructions, they offer a reliable solution for a wide range of high-performance conveying tasks.

Key features:

The 1-ply belts are extremely flexible, making them ideal for tight transfers over nosebars and small pulleys — a perfect match for the AMMdrive SP (Small Pulley) concept. The 2-ply version provides increased mechanical resistance, used in heavy-duty environments and even as a cut-resistant positive drive belt for transporting metal parts with sharp edges.

AMMdrive belts with PVC (polyvinyl chloride) coating offer a smart, economical choice for general conveying applications.

With a working temperature range from -15 °C to +80 °C, they deliver consistent performance in both food and non-food settings. PVC stands out with its natural UV and chlorine resistance, making it especially suited for food industry environments where intense cleaning routines are common.

The material is easy to fabricate, supports a wide range of belt constructions, and provides excellent dimensional stability at a great value.

AMMdrive V belts made with PVC are the most cost-effective solution in the AMMdrive family – ideal for general material handling where reliability and simplicity matter most. Available in 1-, 2-, and 3-ply constructions, they offer the right balance of flexibility and stability for a wide range of conveying tasks.

Key features:

Two fabric options extend the versatility of the AMMdrive V range:

AMMdrive VN belts are made from food-grade PVC, designed to offer a cost-effective alternative to AMMdrive U in hygienic environments. Available in white and light blue, these belts meet industry expectations for visual cleanliness and compliance – making them a practical choice for a wide range of food applications.

Key features:

With high flexibility and reliable tracking, AMMdrive VN belts reduce the risk of misalignment and the maintenance costs that come with it – particularly in systems where belt replacement is complex or time-consuming. They bring the core benefits of AMMdrive technology into price-sensitive areas of food production, without compromising essential performance.