Global

International

With Maestro 2.0 splicing equipment, Ammeraal Beltech has leaped forward in the critical areas of the splicing process: high quality, efficiency, speed, precision, and ease of use.

With Maestro 2.0 splicing equipment, Ammeraal Beltech has leaped forward in the critical areas of the splicing process: high quality, efficiency, speed, precision, and ease of use.

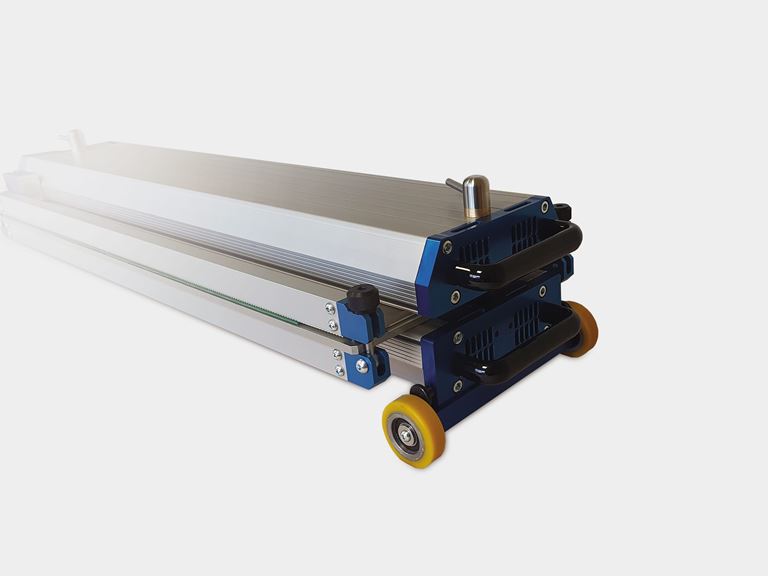

The unique Maestro 2.0 concept confirms Ammeraal Beltech as the leading supplier in global uniform splicing equipment. The compact design makes it easier to fit into a narrow installation area. Structured in modules and therefore lighter than other joining systems on the market, it is also easy to transport around the plant thanks to its wheels.

Its real strength? The connectivity!

VERSATILITY AND TOP CONNECTIVITY

• Modern integrated new controller (internal or external) with HMI screen

• External controller can be used for all presses

• Can be used in combination with double step splice tool for infinite belt width

NEW DESIGN

• Robust clamping bar-bolts, connectors, removable wheels

• Stronger clamp bars for M1850 + M2200

• Smart and various voltage press operation (120/240V or 240/480V or 400V)

• Integrated cooling fans

• Internal compressor for pressurizing splice press

• Pre-heat function

• Compact dimension for use on small conveyors or with short tension device stroke

• Bolt detection

EASY and SAFE

• Weight divided into 4 main parts, making it easier to manipulate the press into work location.

• Proven and highly appreciated low press body profile height from Maestro 1.0, easy to fit into a narrow installation area.

• Easy local transportation by removable wheels

• Individual M2.0 press main parts are lighter then all main parts competition presses components.

• Less production downtime thanks to the ease of replacing individual parts

• Cold pressure zone around heated area to close-in molten area

PRECISE

• Third thermocouple insures correct splice settings, all external factors are eliminated.

• Compressor keeps pressure maintained