Global

International

The coatings used on Synthetic Belts are called polymers and can be made of various materials which have influence on the suitability of the belt in a certain application.

Polymers can be separated into two different groups: thermoplastic or thermoset.

Mainly used compounds for coatings are:

PVC | Polyurethane | Polyolefin | Polyester

Polyvinyl chloride, commonly abbreviated to PVC, is a widely produced plastic. PVC is a type of thermoplastic polymer that is flexible and durable, and therefore suitable for use on conveyor systems.

Main PVC coating types:

Product features:

Industries:

Product features:

Industries:

Product features:

Typical application:

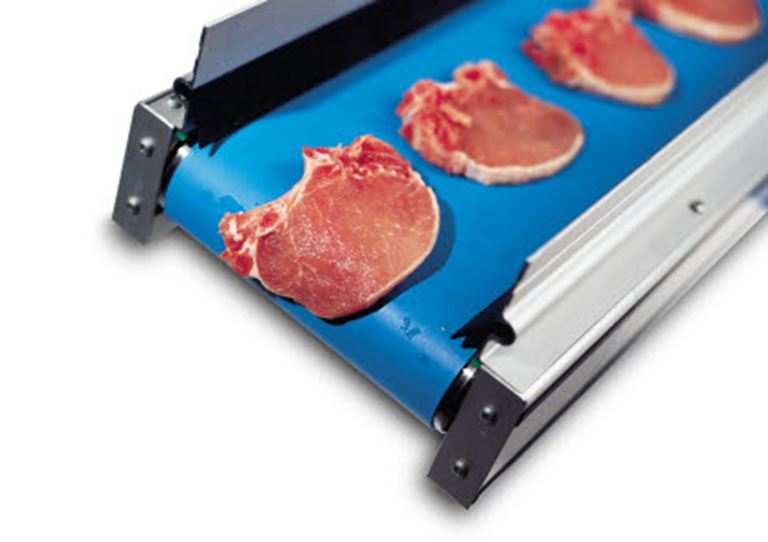

Polyurethane belts are mainly used in the Food Industry. Due to its structure, polyurethane belts do not give off damaging toxins or chemicals. Polyurethanes for process and conveyor belting can be either thermoplastic – TPU, or thermoset – PUR. Thermoplastic polyurethane coating material excels through its exceptional resistance to grease, oils and chemicals.

Main polyurethane coating types:

Product features:

Industries:

Main features

Benefits

Typical applications

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Main product features:

• Low electrical surface resistance of the top and bottom side

• Low electrical volume resistance of the full belt thickness

• Flexible belt carcass

• Wear-resistant top cover

Benefits:

• ESD-safe, prevents product damage from electrostatic discharge

• No harmful ESD affecting operators/workers

• Nonpolluting, closed belt top surface

Dedicated to the Electronics Industry.

Polyolefins are the largest group of thermoplastics; they are polymers of simple olefins such as ethylene. Polyethylene is probably the polymer you see most in daily life; it is the most popular plastic in the world.

Main polyethylene coating types are:

Polyester is a category of polymers that contain the ester functional group in their main chain. Our polyester coating type:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Fabric and Felt belts are used in a wide variety of material transport applications such as car manufacturing, food processing and heavy industry. Felt is a non-woven fabric. The most important raw material for belting fabrics is polyester.

Main fabrics used:

By mixing polymers together, Ammeraal Beltech produces variations on PVC or PU called “Special Blends”. E.g.:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Product features:

Industries:

Featured Products are only a sub-set of our extensive product line-up, the widest in the business. Our experts can help you find the right belt. Fill-in the contact form or go to our Contact page.

| Article Code | Description | Belt thickness | Hardness top side | Info | |

|---|---|---|---|---|---|

| internal AB method KV.002 | according to ISO 868 | Minimum pulley diameter | |||

| total | top side | flexing | |||

| SBNO570090 | Nonex EM 5/1 00+02 white FG | 0.03 in. | 65A | 0.24 in. | |

| SBNO571990 | Nonex EM 8/2 A18+05 light blue FG AM | 0.11 in. | 65A | 1.57 in. | |

| SBNO573325 | Nonex EM 10/2 00+A54 white FG | 0.12 in. | 65A | 1.57 in. | |

| SBNO573360 | Nonex EM 10/2 00+07 light blue FG AM | 0.1 in. | 65A | 1.57 in. | |

| SBNO573400 | Nonex EM 10/2 00+15 white FG | 0.12 in. | 65A | 2.36 in. | |

| SBNO573500 | Nonex EF 10/2 A18+07 white FG | 0.13 in. | 65A | 1.97 in. | |

| SBNO575230 | Nonex EM 8/2 00+05 white AS FG | 0.08 in. | 65A | 0.98 in. | |

| SBNO575232 | Nonex EM 8/2 00+A15 white AS FG | 0.11 in. | 65A | 0.98 in. | |

| SBNO575233 | Nonex EM 8/2 00+A18 white AS FG | 0.09 in. | 65A | 0.98 in. | |

| SBNO575700 | Nonex EM 8/2 00+05 light blue AS FG AM | 0.08 in. | 65A | 0.98 in. | |

| SBNO575703 | Nonex EM 8/2 00+A18 light blue AS FG AM | 0.09 in. | 65A | 0.98 in. | |

| SBNO576010 | Nonex EF 10/2 A18+07 light blue FG AM | 0.13 in. | 65A | 1.97 in. | |

| SBNO572780 | Nonex EM 8/2 00+03 light blue AS FG AM | 0.06 in. | 65A | 0.79 in. | |

| SBNO571320 | Nonex EM 8/2 00+03 white AS FG | 0.06 in. | 65A | 0.79 in. | |

| SBNO510453 | Nonex EF 45/3 12+13 white M2 AS FG | 0.28 in. | 70A | 13.78 in. | |

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, color and material combination for your specific requirements and local stock availability.