Global

International

In the world of conveyor systems, efficiency is vital. Every minute of downtime can translate into significant losses for businesses relying on smooth operation. Introducing ZipLock®, the latest innovation from leading conveyor belting manufacturer Ammeraal Beltech. Now available in the US, ZipLock® revolutionizes the way belts are swapped, slashing maintenance costs and downtime while ensuring smooth, silent operation.

“ZipLock® is the answer to the industry's pressing need for swift and hassle-free belt replacements,” says Jeff Cabalquinto. “With the ZipLock® method, belt swapping is no longer a laborious task but a quick, do-it-yourself splice that takes just minutes to complete.”

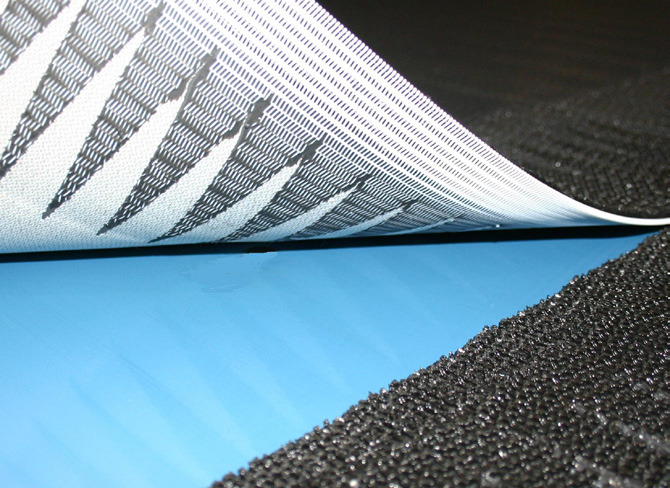

Key to ZipLock's® effectiveness is its unique design, which facilitates easy and fast belt exchange without compromising performance. Unlike conventional methods that rely on metal or plastic mechanical belt fasteners, ZipLock® boasts a nearly invisible connection that guarantees a smooth and quiet belt run. This feature makes it particularly well-suited for applications in environments where minimizing the time required to replace belts is crucial – such as airports and distribution centers – or where belt location is inaccessible for maintenance.

Jeff adds, “The ZipLock® method involves the use of special belt inserts that are spliced together with a strong finger splice. At the site, the ZipLock® ends are seamlessly connected by inserting a plastic pin, resulting in a continuous belt cover over the splice area. Not only does this ensure operational safety and reliability, but it also eliminates the need for heavy equipment, making on-site installation a breeze.”

One of the most compelling advantages of ZipLock® is its cost-effectiveness. By significantly reducing maintenance time and costs associated with downtime, ZipLock® offers businesses substantial savings compared to traditional splicing methods. According to Ammeraal Beltech's calculations, ZipLock ®results in an average cost savings of 30% when compared to traditional splicing, not including additional savings from shorter downtimes.

"With ZipLock®, we're empowering businesses to optimize their conveyor systems like never before," says Jeff. "By streamlining the belt replacement process and minimizing downtime, ZipLock® enables our customers to maximize productivity and profitability."

To learn more about ZipLock® and how it can benefit your operations, visit https://www.ammeraalbeltech.com/en-US/products/synthetic-belts/fabrication--accessories/ziplock/