Global

International

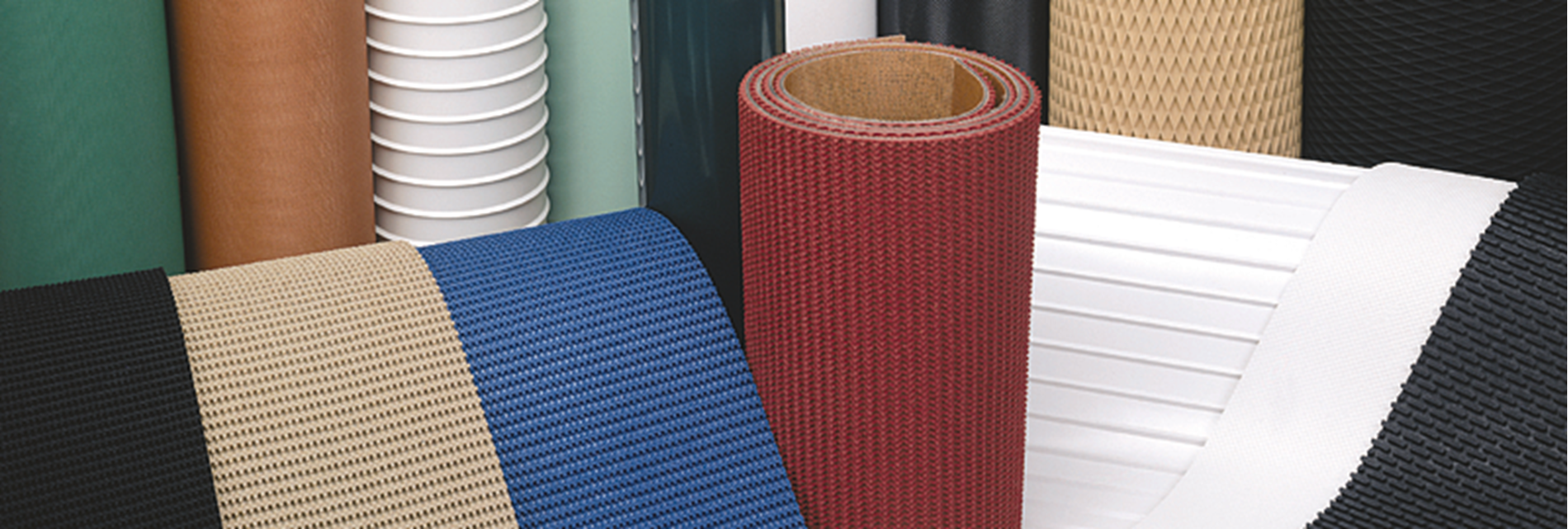

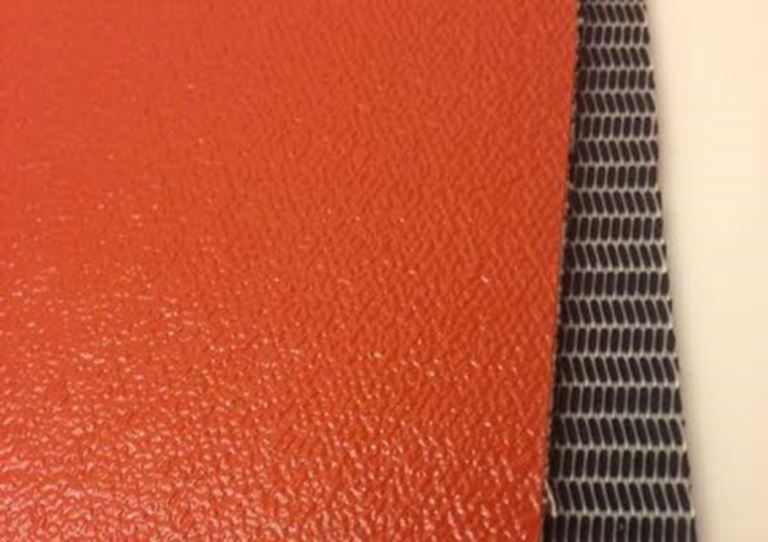

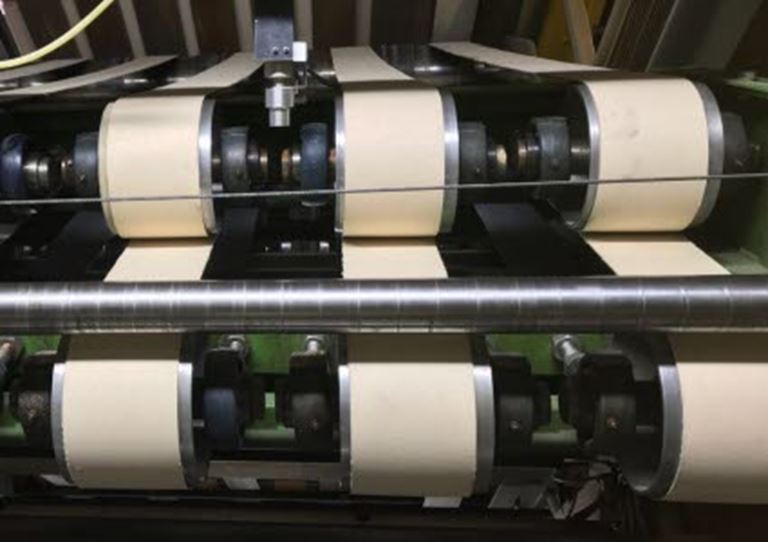

Ammeraal Beltech utilizes a wide variety of raw materials in manufacturing our lightweight rubber belting products.

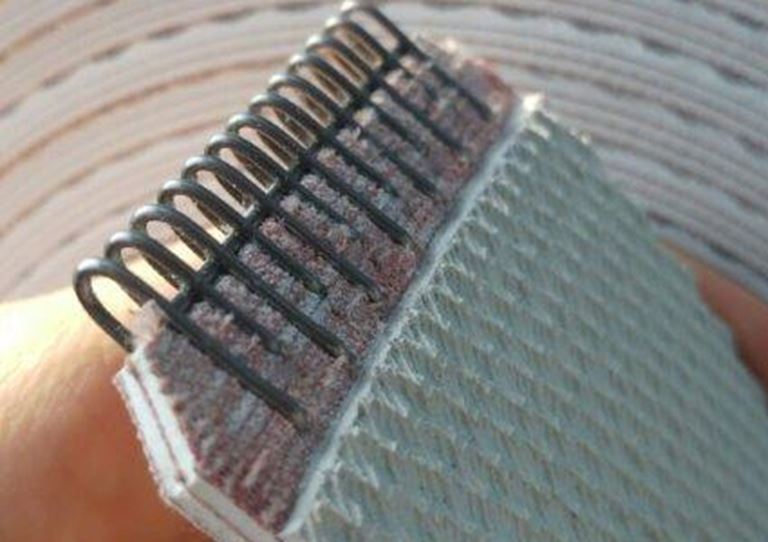

Specifications range in many thicknesses. We produce both unsupported and fabric inserted materials.

General characteristics:

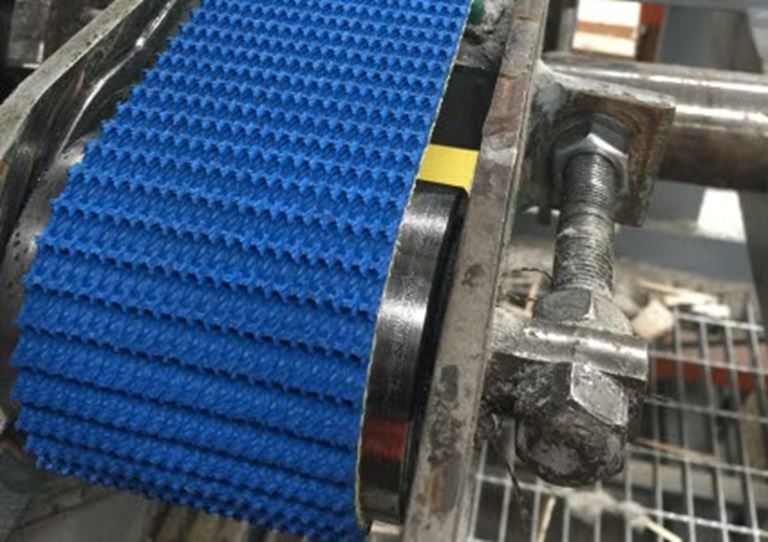

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

Cardboard

Car Industry

Featured Products are only a sub-set of our extensive product line-up, the widest in the business. Our experts can help you find the right belt. Fill-in the contact form or go to our Contact page.

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, color and material combination for your specific requirements and local stock availability.