全球的

全球的

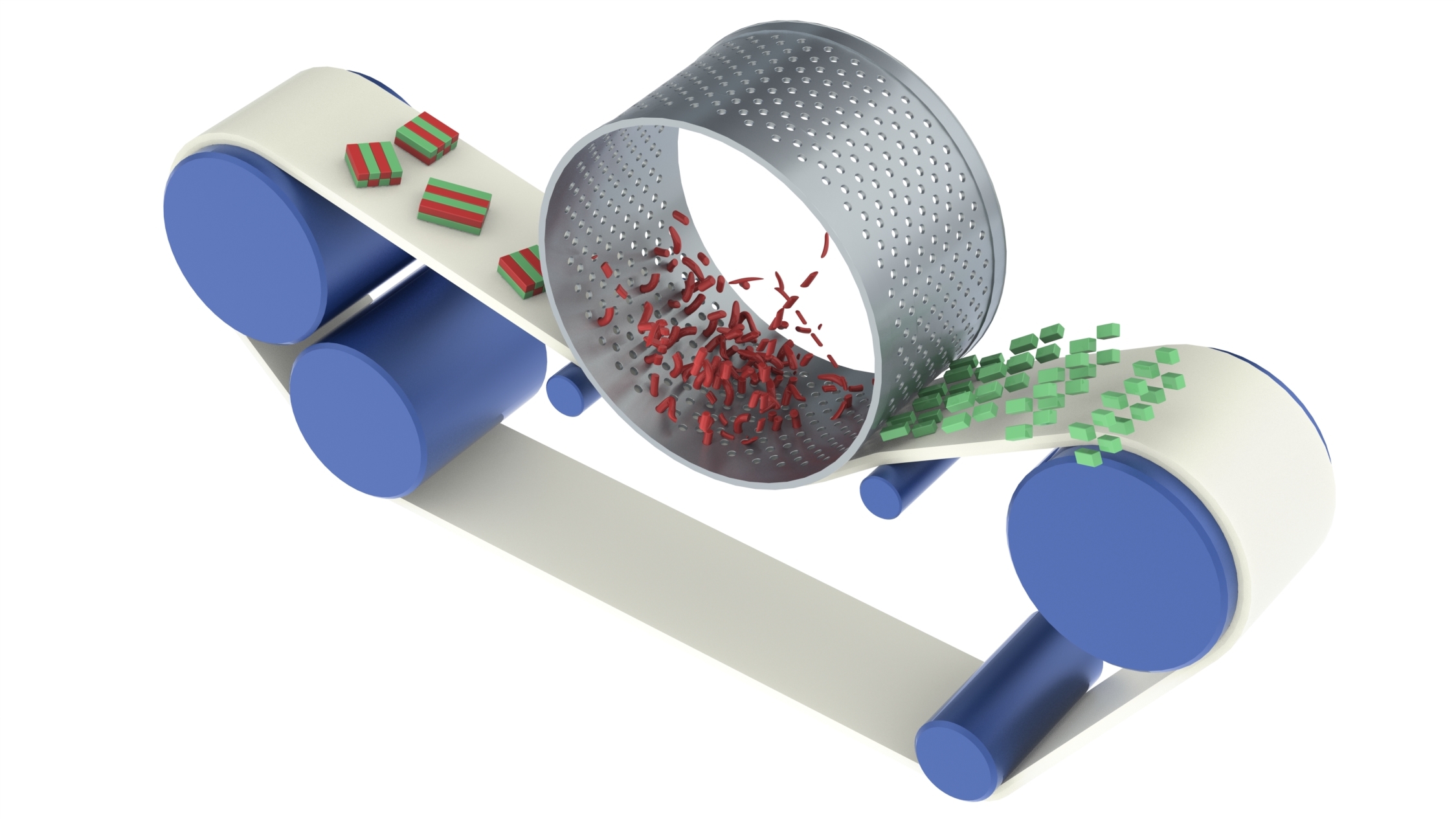

Soft separation is one of the most demanding stages in food processing. The right belt can determine everything from product yield to food-safety performance. We’re excited to expand our portfolio with a new, highly durable Amsqueeze RS separator belt, designed for high-capacity and high-force machines.

Why is Amsqueeze RS a crucial addition to the Amsqueeze belt series?

Amsqueeze belts are process belts used across the meat, poultry, fish, and broader food industry to separate soft material from harder components. They help create base products for hamburgers, sausages, fish sticks, chicken burgers, and more, and are also widely used for de-packing and waste recovery. This includes:

The Amsqueeze RS (Resilient) variant was designed especially for high-capacity and high-force separators (such as pork or turkey processing). The RS version has been developed for the high-pressure soft separating machines. To achieve this, we added a combination of different coating, reinformed fabrics, and a new Chevron profile.

The capabilities include:

Find out more about the new expansion to the AmSqueeze here.