Global

Internationell

uni, the most trusted name in modular belting, also offers a range of innovative accessories for its Plastic modular belts including:

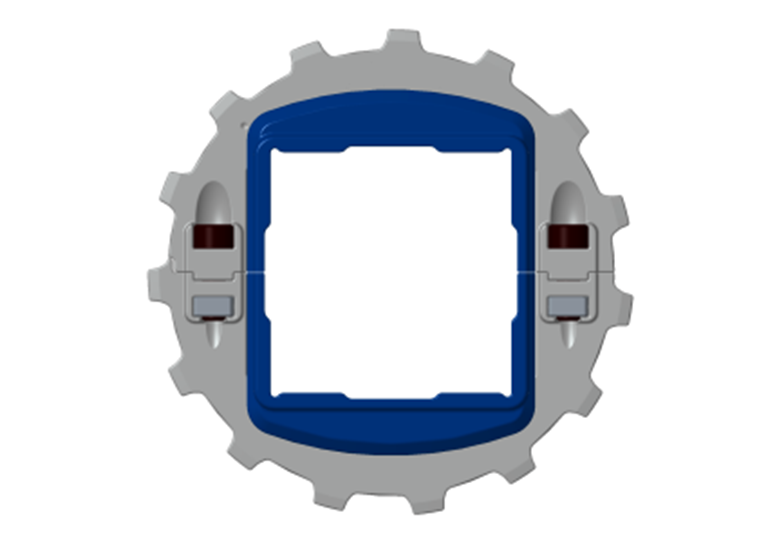

With unique features that combine all the benefits of a traditional two-part sprocket system – ease of installation and replacement, less downtime and lower maintenance costs – with unparalleled advantages in hygiene and cleaning, this innovative belt sprocket is delivering outstanding hygienic performance in demanding applications across the food industry.

- Helping to prevent food ingress

- Reducing bio-film build up

- Making sprocket, shaft and belt cleaning easier

- Reducing water and cleaning agents consumption

Proven to be the best in test

During in-depth washdown testing of a selection of commonly available sprocket designs conducted by the DTU Center for Hygienic Design at the Technical University of Denmark, the uni UltraClean Two-Part Sprocket proved itself to be the most hygienic belt sprocket system for use in the food industry.

Our new Sprockets offer all the ease and convenience of a bolt-together modular Two-Part Sprocket, but their most unique and revolutionary feature are the built-in adapters.

The adapters make it possible to install the uni UltraFit Two-Part sprocket on different shaft sizes. Serving as spacers too, they automatically guarantee perfect distance between the sprockets, ensuring ideal alignment of sprockets across the belt width.

Adapters are available for popular bore sizes and in two widths:

Suited for the following uni Modular Belt series:

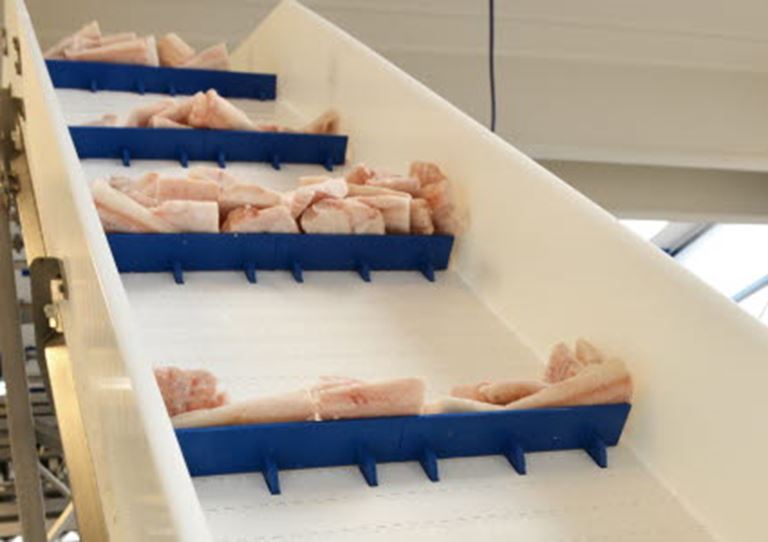

Pop-up flight for elevator conveyors is big news in the food processing industry – a real innovation that can bring benefits for YOUR business.

Pop-up flight does just what the name says. It pops up at the foot of the conveyor incline to support the food as it moves up the elevator, holding it steady. Then, once the product’s been successfully discharged, the flight pops down again so an automatic scraper can clean up the belt – especially helpful for sticky, clingy food products. So you won’t have to sweep up costly wasted product from the floor as the belt moves on its return path.

What’s more, it’s simple to fit our Pop-up flight to your existing uni MPB modular belt system – no secondary drive motors or complex controls are needed. It’s also easy to maintain, and it contributes significantly to plant hygiene.

Download product information and find out how the Pop-up flight can bring dramatic savings to your business!