Global

Internationell

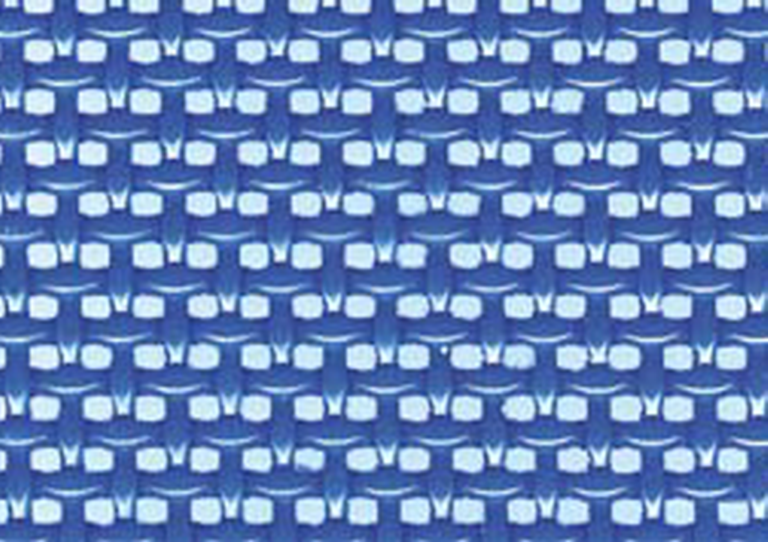

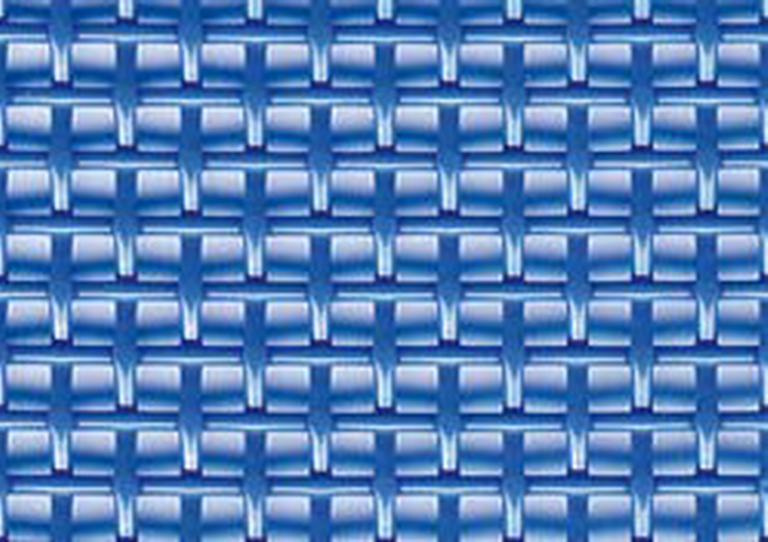

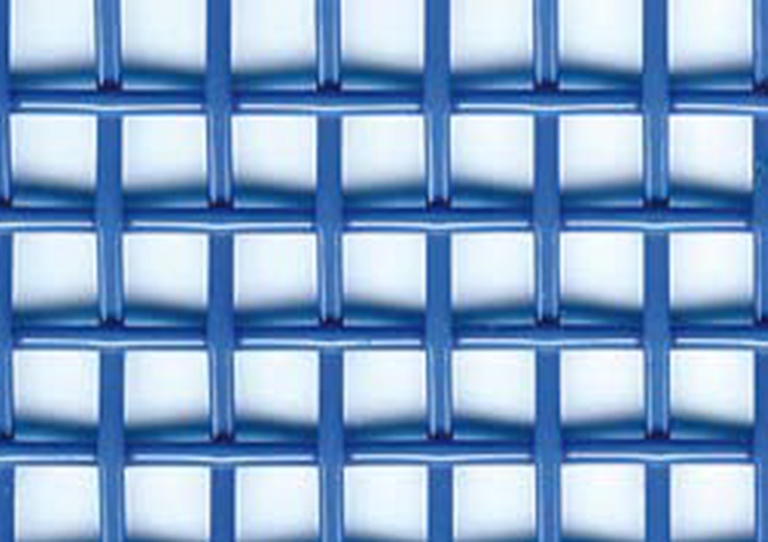

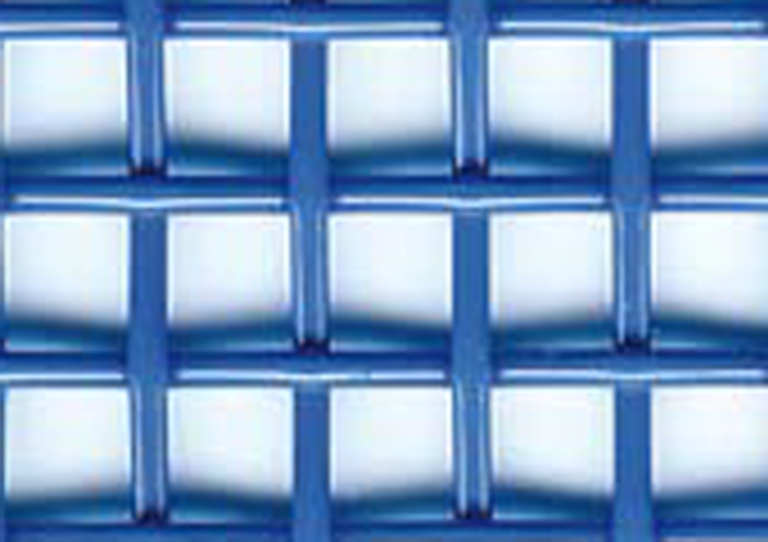

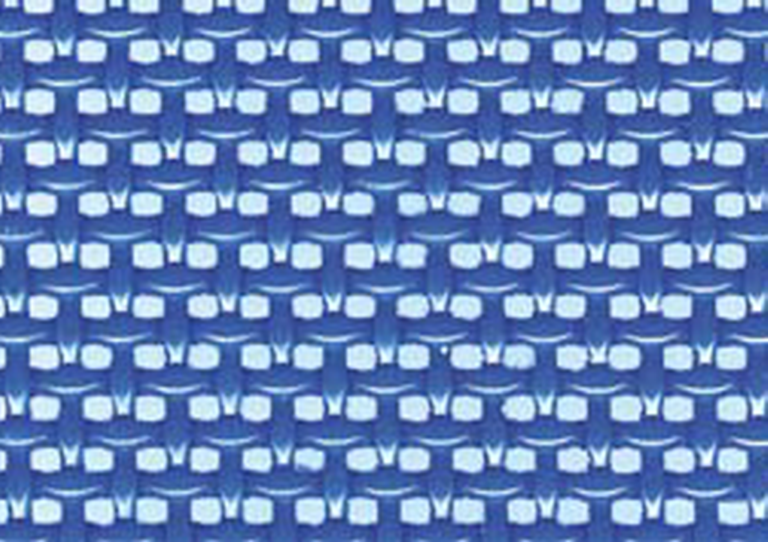

Huvudapplikationen för Ammeraal Beltech Ultrascreen-band är urvattning och torkning av sköljda färska, skurna grönsaker. Diverse olika nätstorlekar för skärmmaterialet tillåter den perfekta lösningen för varje produktstorlek. Kombinerat med ett stort öppet område blir resultatet högsta möjliga produktionsutgång.

Ultraskärmsband används även i kylningsprocesser, återvinning av använt tvättvatten, spillvattenbehandling, filtrering, sållning och klämning.

Fördelar:

*Beroende på nätstorlek

*Beroende på nätstorlek

*Beroende på nätstorlek

*Beroende på nätstorlek

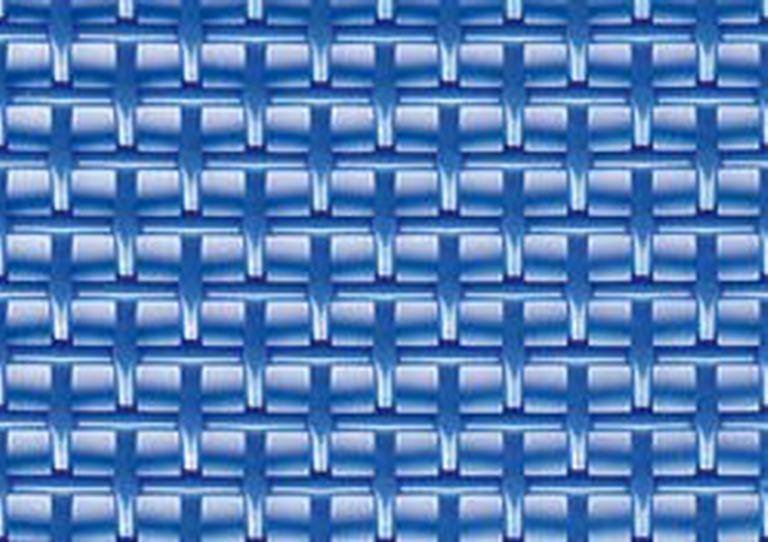

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

Ultrascreen PRO comes with a variety of different teeth and sprocket styles to fit your application. The positive drive system has the following benefits:

The Ultrascreen PRO belts can be installed on new positive drive conveyors or as retrofits on friction-driven conveyors.

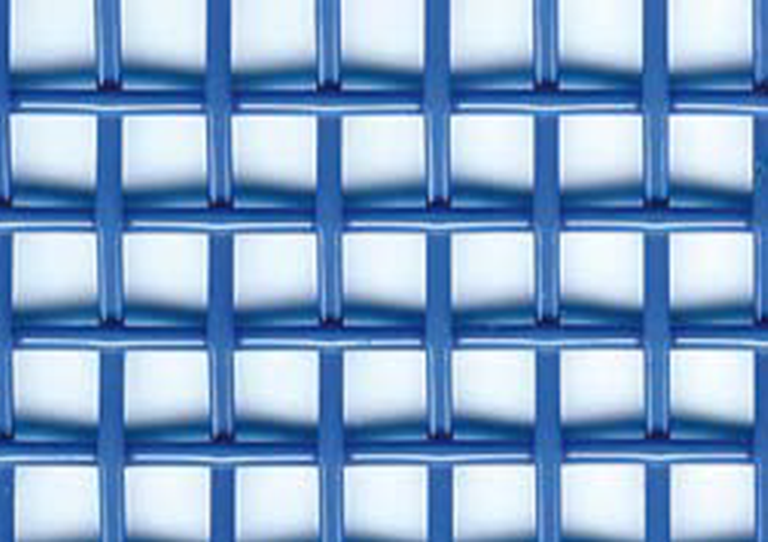

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

Every segment of the Food Industry runs the risk of foreign body contamination, with heavy consequences that include everything from disruptive claims affecting the brand reputation, all the way to very expensive product recalls. For those reasons, we have the Ultrascreen XMD edges available. The edges are X-ray and metal-detectable. Should the edges or cleats pollute your product, it will be picked up by your metal detector.

*Depending on mesh size

*Kontakta din lokala Ammeraal Beltech-expert för att avgöra lämpligaste bandtyp, färg och materialkombination för dina specifika krav och lokalt tillgängligt lager.