Global

International

The last Food Industry article introduced some potential food safety threats and the importance of health standards on site. Nevertheless, the food safety topic is vast and one brief text can only cover so much. Therefore, this week, we shall take a closer look at specific industry’s areas and their biggest requirements when it comes to preserving customers’ health.

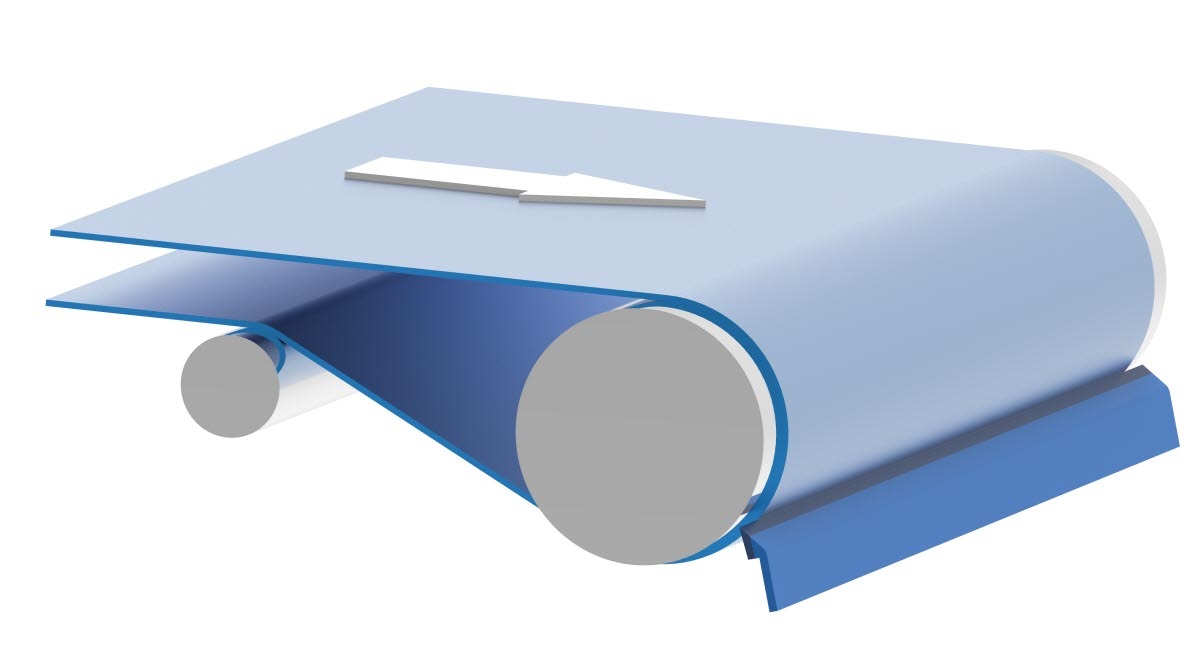

A sandwich is a go-to breakfast of millions, this makes the bread one of the most demanded products in the world. Well, it’s not a surprise since there’s nothing better than a scent of a warm bread. So, what is the biggest hurdle of making bread? Cross-contamination! To be more precise, it is the risk of exposing the belt and product surfaces, intentionally or not, to the drops, taints and splashes from other food products, as well as other hazards in form of a liquid or dust. To avoid it, the producer must keep the equipment and its components clean and sterile, not to mention introducing worker health measures. The handling of bread dough is a sticky business. Hence, it is utmost important to use surfaces which minimise the bacteria growth, such as Homogeneous Belts, Anti-Microbial Belts, Non-fray Belts and Light Blue Belts, and which are especially designed to release the dough easily eventually with the additional feature of scrapping. Scrapping is a process of physical removal of leftovers from the belt’s top cover, however the constant interaction between the two can decrease the lifespan of the equipment, this is why Ammeraal Beltech has developed ultra-durable and metal detectable scrapping product UltraScraper.

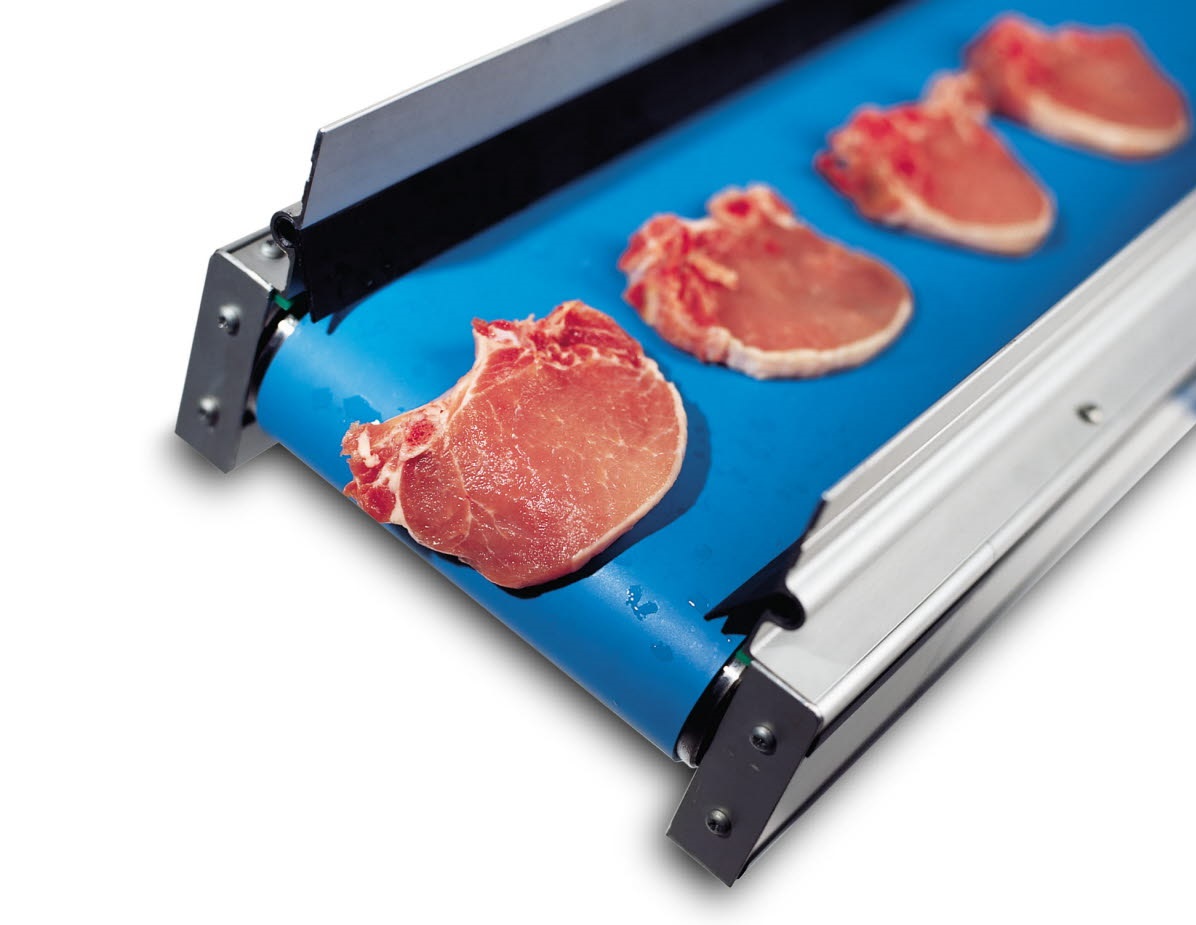

There is nothing more wasteful than meat going spoiled. During its processing, dirty environment with presence of blood, fat and bones can effectively pollute the product. For that reason, one can say, it is mandatory to use surfaces which will never soak or hold any contaminants from previously handled meats, even after the sanitation. Moreover, belts can develop cracks, either by extensive usage or contact with sharp edged bones for example. Then the food particles get into those cracks, grooves and cavities to slowly spoil the entire batch. The whole incident of replacing belts and recalling the batch is expensive. It is much cheaper to invest in solutions with which the above-mentioned problems do not occur. Nonex Food Grade processing Ammeraal Beltech belts are crack-free food grade belts which are characterised by excellent sanitation standards and utterly long lifespan, enabling its users to never face the problem of meat going bad.

Fresh fish scent is not bad whatsoever. So, how come sometimes we purchase a cod, and it’s a smelly one? Speed is the answer. Naturally, the sanitisation and antibacterial measures are very important when handling any food, but in Fish & Seafood industry there is also an obligation of the handling processes to be swift. Otherwise, the tender fish meat will slowly begin its decay before reaching freezers or cooling boxes. Ammeral Beltech’s uni MPB was created to not only outperform all sanitary standards, but also to cut down the time needed for maintenance. Quick belt replacement is assured by especially designed 8mm diameter pins, as well as drainage properties keep the cleaning fast while saving water. With this solution, the only smelly fish on a supermarket’s shelf will be the infamous surströmming.

All in all, when we compare the three food sectors in this article, we can deduce that sanitation and trouble-free equipment are key factors of food safety, no matter the exact segment. Thankfully, these days, conveying solution providers, such as Ammeraal Beltech, understand food companies’ needs completely and implement ever-modernising systems that keep the product fresh and free of foreign bodies.