Global

Internacional

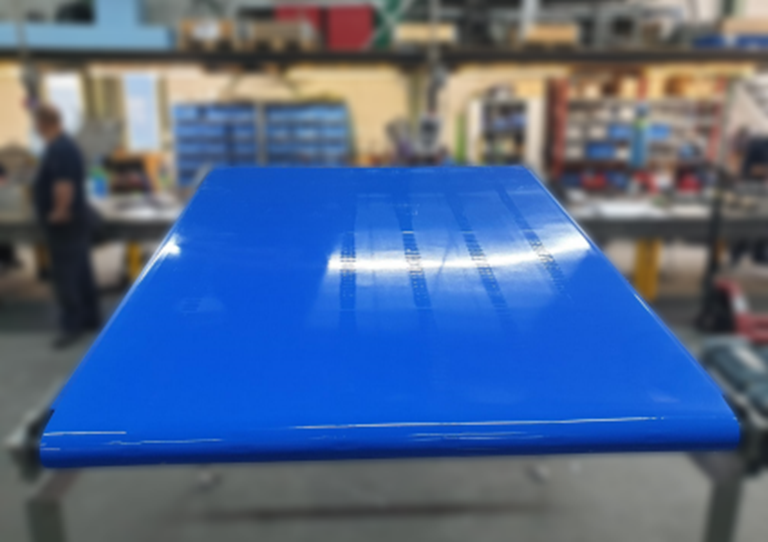

AMMdrive is a hybrid belt solution that merges the key benefits of synthetic, modular, and homogeneous belts into one design. It delivers positive drive, self-tracking, durability and hygienic performance without slippage or elongation – even in high-load or high-temperature environments.

Positive driven fabric belts provide some unique features compared to other belting solutions on the market. Where tracking usually becomes an issue, AMMdrive can be a great solution to many heavy duty applications. High speed? Belt slippage? High pollution? High temperature? You name it and we propose a solution.

Conveyor belting benchmark

Fabric-based synthetic belts or modular plastic belts.

Problem description

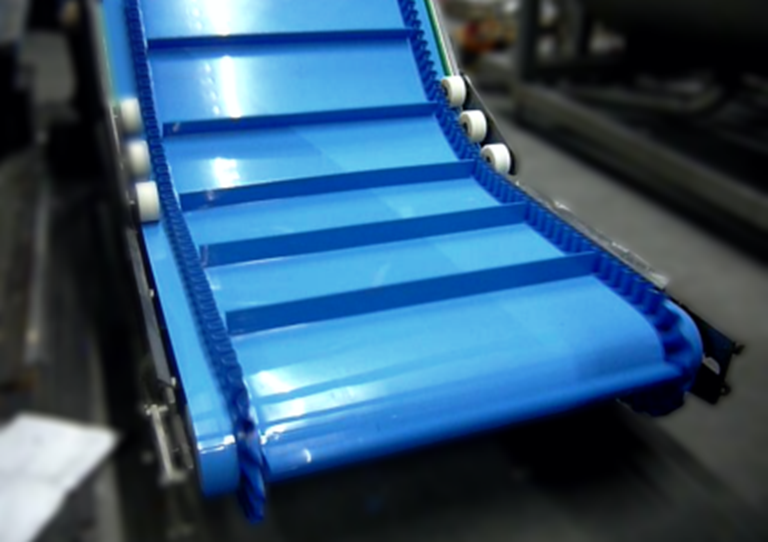

Friction-driven belts in high-speed systems suffer from elongation, especially under start/stop cycles and heat buildup from friction. They require frequent retensioning and are often tracked using ropes, which can wear out or detach. At speeds above 2 m/s, even slight misalignment can lead to belt damage. While modular belts don’t elongate, they become excessively noisy at high speeds.

AMMdrive solution

AMMdrive belts provide precise, stable tracking at high speeds without elongation or slip, thanks to the positive drive and self-tracking PRO lugs. There’s no need for retensioning, and the system runs quietly and reliably, even under demanding start/stop, multi-cycle operations – making it ideal for fast-paced, synchronized processes.

Conveyor belting benchmark

Fabric-based synthetic belts, often with V-guides for tracking.

Problem description

In wide and short conveyors – where the length-to-width ratio is low – belts are prone to severe tracking issues. This leads to frequent belt damage, guide wear, and unexpected downtimes due to misalignment. Traditional V-guides wear out or detach under the high lateral forces and heat caused by friction.

AMMdrive solution

AMMdrive belts with self-tracking PRO lugs offer a 100% reliable tracking system, even on square or oversized conveyors. Tracking is achieved through positive sprocket engagement and lateral wear strips that guide the belt across the entire conveyor length. This eliminates the need for tensioning or V-guides, extending belt life and ensuring stable, low-maintenance operation.

Conveyor belting benchmark

Fabric-based synthetic belts, often friction-driven with central drive or tensioned V-guides.

Problem description

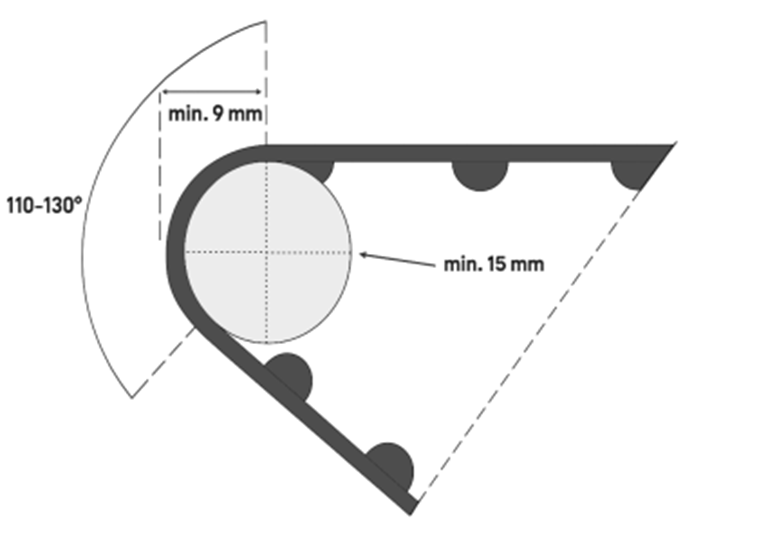

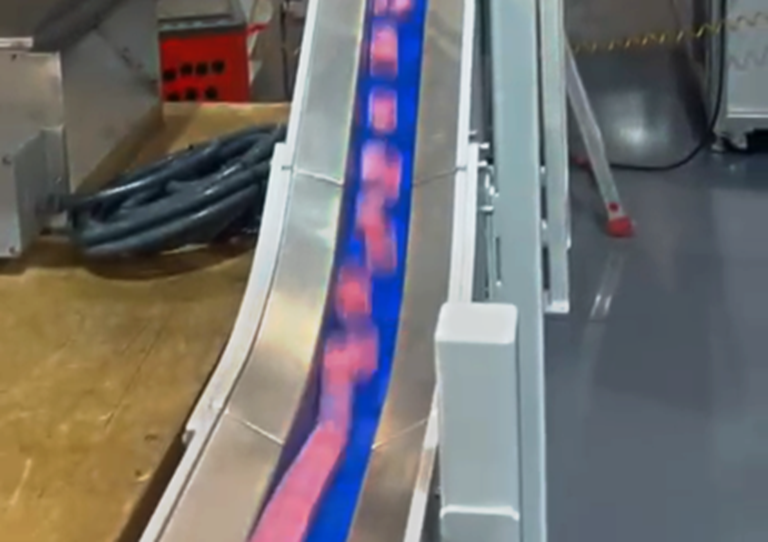

Wide Z conveyors suffer from belt tension buildup in bends, especially in center-driven or friction-driven designs. This causes the belt to jump out of its path, overstressing V-guides – particularly in wide configurations. Complex mechanical supports like grooved rollers, omega drives, and guide strips are required, increasing cost, space, and maintenance.

AMMdrive solution

Using PRO lug technology, AMMdrive belts enable low-tension, positive tracking in wide Z elevators – without grooved pulleys or V-guides. The belt is supported by dual-edge lugs and center support rollers, distributing force evenly and ensuring smooth, stable running – even in conveyors up to 1500 mm wide. This simplifies construction, improves hygiene, and reduces mechanical stress in critical bend areas.

Conveyor belting benchmark

Fabric-based synthetic belts or modular plastic belts.

Problem description

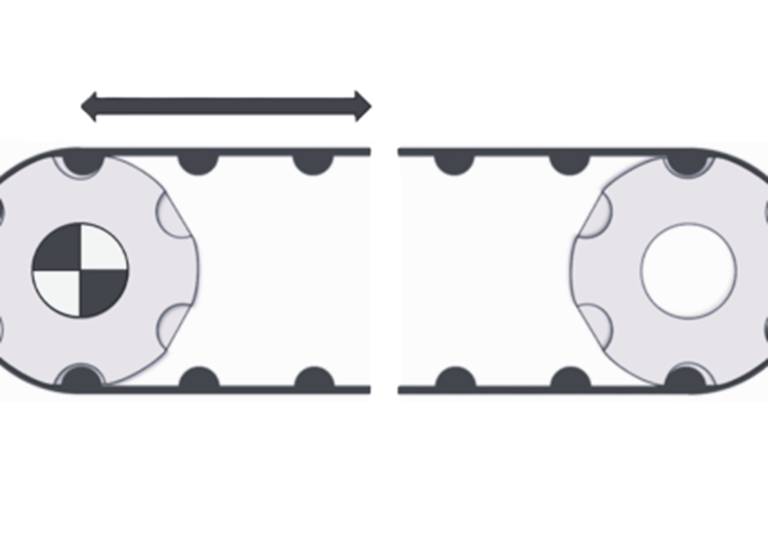

Bidirectional conveyors usually require a central omega drive, which adds bulk, mechanical complexity, and extra weight to the conveyor frame. Modular belts also need a catenary sag, further increasing space requirements and limiting design flexibility.

AMMdrive solution

AMMdrive belts can operate in both directions without a central omega drive. Thanks to the positive drive system, they can push as well as pull, enabling compact, low-maintenance bidirectional conveyors with fewer components.

Conveyor belting benchmark

Fabric-based synthetic belts or modular plastic belts.

Problem description

Synthetic belts require high tension and are prone to tracking issues, especially on small pulleys. This leads to slippage, misalignment, and short belt life. Modular belts can handle small diameters, but their hinged design traps debris, making them unsuitable for hygienic applications.

AMMdrive solution

AMMdrive belts – especially in the SP (Small Pulley) range – are designed to run over tight pulleys and nosebars without slippage or tracking adjustments. They offer a clean, compact, and maintenance-friendly solution for small pulley systems.