Global

International

All AMMdrive belts are tailored to your specific needs. On the top of welding our PRO drive lugs, based on your specific needs, we weld cleats, mount bordoflex, splice belts endless and punch perforations.

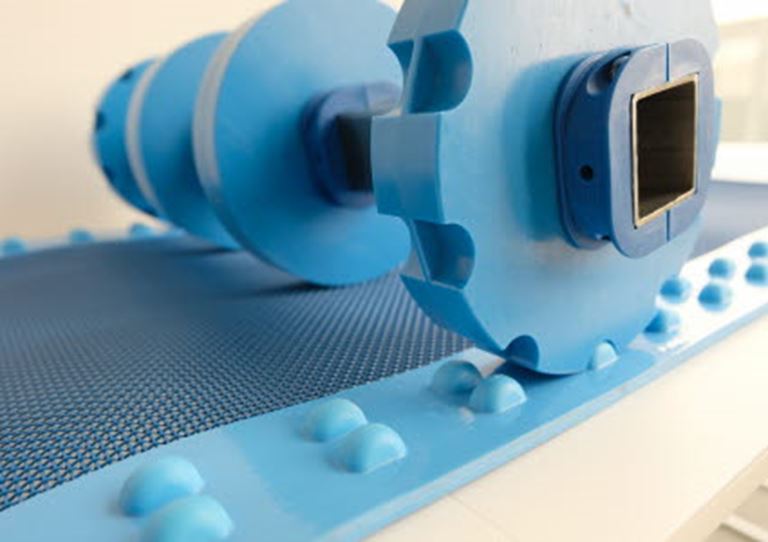

On the top of that, our belts are supplied with sets of drive sprockets and support rollers in 24 different sizes to match your needs.

All AMMdrive belts are tailored to your specific needs. On the top of welding our PRO drive lugs, based on your specific needs, we weld cleats, mount bordoflex, splice belts endless and punch perforations.

On the top of that, our belts are supplied with sets of drive sprockets and support rollers in 24 different sizes to match your needs.

All sprockets are available with a variety of bore types – from round 20 mm with keyway to square 60×60 mm – to accommodate different shaft and drive configurations.

PRO sprockets come in several specialized versions to suit specific environments:

AMMdrive belts utilize a highly reliable mini finger splice, featuring 8x5 mm fingers. This splicing method ensures a strong and consistent bond by providing a large surface area of contact between the belt ends. This design not only offers exceptional durability but also maintains the belt's flexibility.

For more demanding and heavy-duty applications, especially with PVC and TPE belts, a step splice can be used. This splicing method is known for its enhanced tensile strength and durability, making it perfect for heavy loads.

In addition to endless splicing, AMMdrive belts can also be fitted with mechanical fasteners. These fasteners come in stainless steel for general use and plastic for metal detector applications.

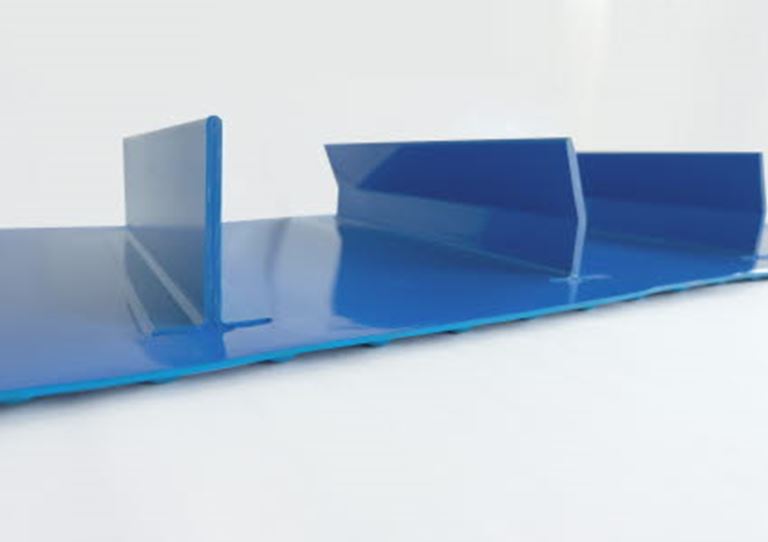

Bordoflex sidewalls add another layer of customization to AMMdrive belts, with each material offering unique options.

This wide variety ensures that each belt type can be tailored to specific application needs, from gentle product handling to heavy-duty edge containment.

AMMdrive belts offer a versatile range of cleats to suit various applications across TPU, TPE, and PVC materials.