Global

International

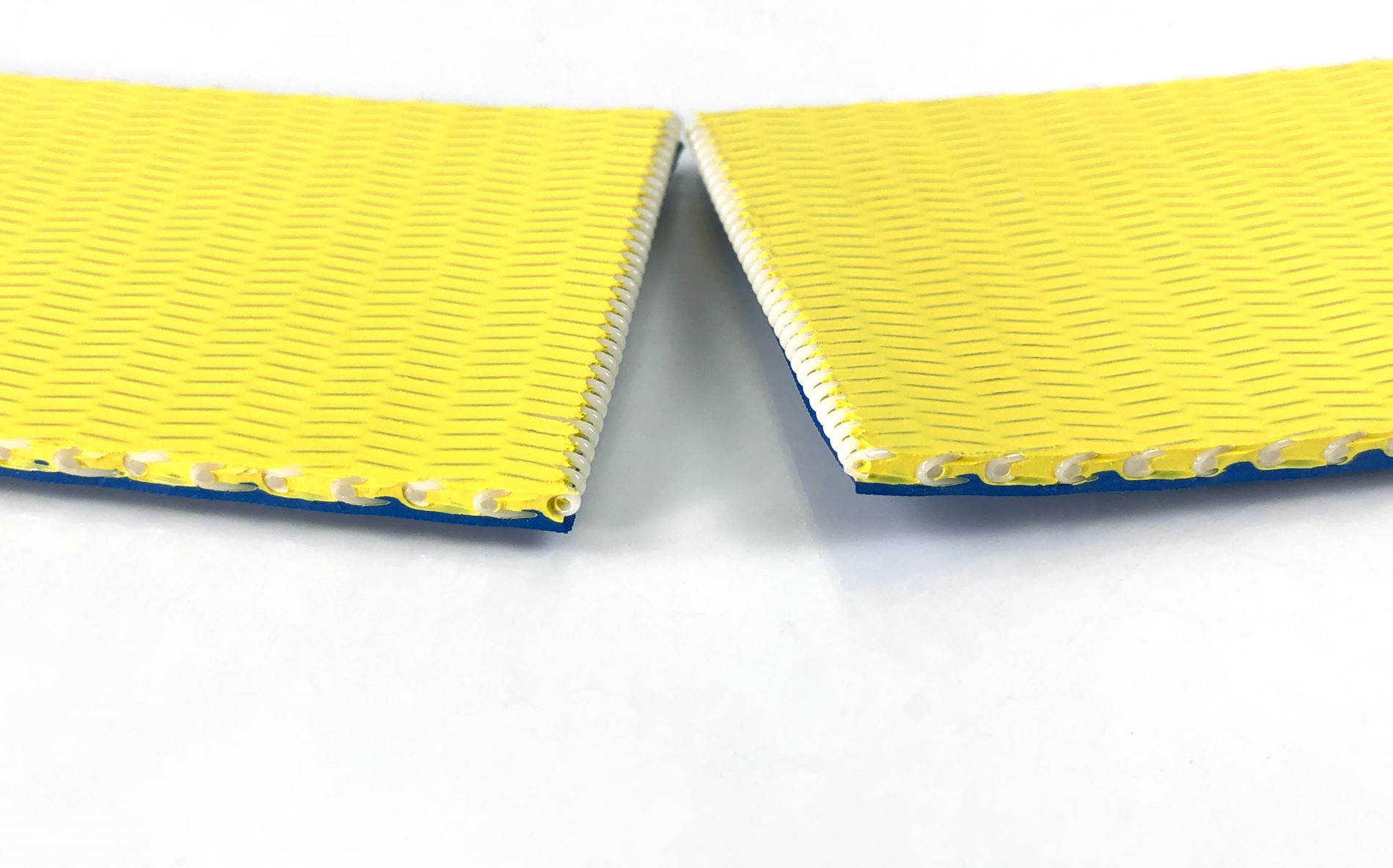

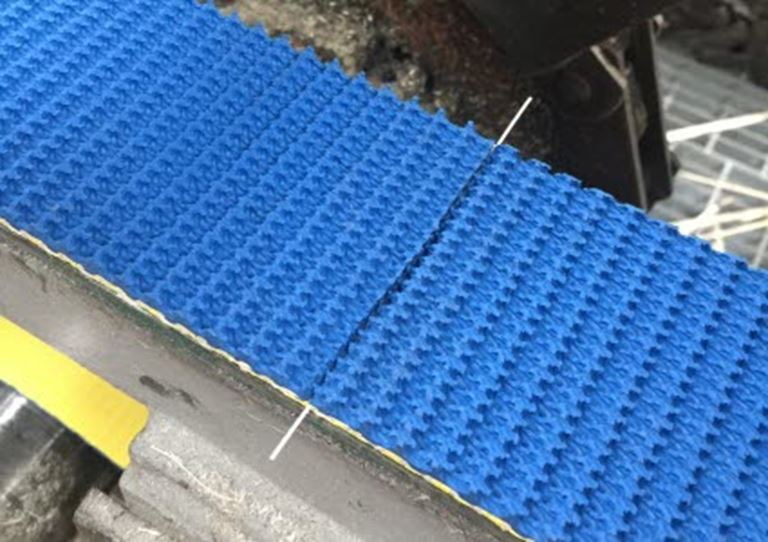

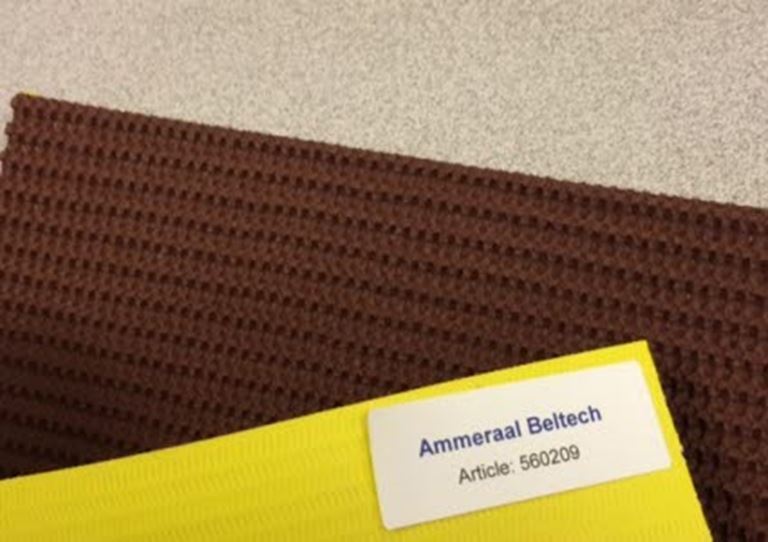

ZipLink® range is a highly practical and cost-effective belting solution for various industries and purposes. Its unique mesh structure allows for convenient splicing without special tools, reducing downtime and increasing productivity. What is more, it can be customised with a variety of top-cover materials.

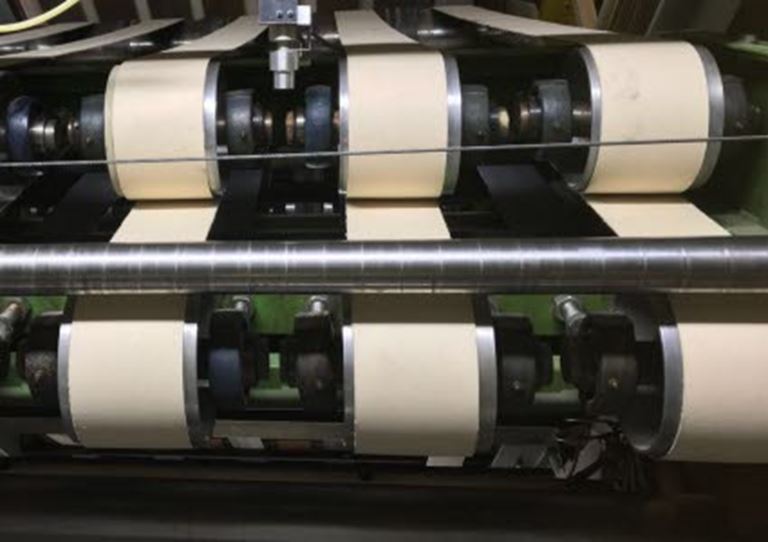

ZipLink® Belts offer users in a variety of different industries an outstanding range of product benefits, such as a more flexible design which allows for the repair or replacement of just small sections of the belt.

ZipLink® product range now includes over 30 problem solving belt constructions combining time tested rubber cover materials with a structured spiral link mesh that can be easily spliced at any length.

The ZipLink® construction eliminates points of weakness because there is no loss of strength in the splice area, making the belts stronger so they last longer than belts of other seamed or fused materials.

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

General characteristics:

Main applications in belting:

Characteristics:

Main applications in belting:

Characteristics:

Main applications in belting:

Featured Products are only a sub-set of our extensive product line-up, the widest in the business. Our experts can help you find the right belt. Fill-in the contact form or go to our Contact page.

*Consult your local Ammeraal Beltech expert to determine the most appropriate belt type, colour and material combination for your specific requirements and local stock availability.